Nissan Sentra Service Manual: Replacement operations

Description

This section is prepared for technicians who have attained a high level of skill and experience in repairing collision- damaged vehicles and also use modern service tools and equipment. Persons unfamiliar with body repair techniques should not attempt to repair collision-damaged vehicles by using this section.

Technicians are also encouraged to read Body Repair Manual (Fundamentals) in order to ensure that the original functions and quality of the vehicle can be maintained. The Body Repair Manual (Fundamentals) contains additional information, including cautions and warning, that are not including in this manual. Technicians should refer to both manuals to ensure proper repairs.

Please note that these information are prepared for worldwide usage, and as such, certain procedures might not apply in some regions or countries.

The symbols used in this section for cutting and welding/brazing operations are shown below.

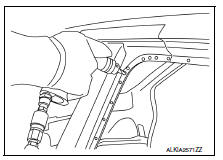

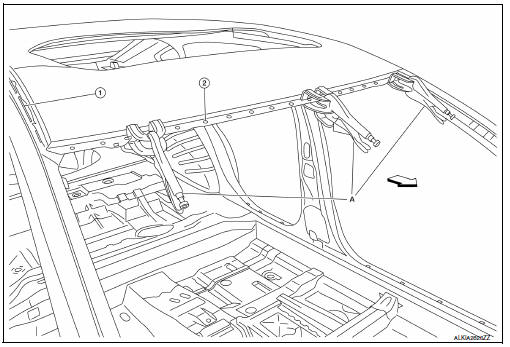

- Front pillar butt joint can be determined anywhere within shaded area as shown in the figure. The best location for the butt joint is at position A due to the construction of the vehicle. Refer to the front pillar section.

- Determine cutting position and record distance from the locating indent. Use this distance when cutting the service part. Cut outer front pillar over 60 mm above inner front pillar cut position.

- Prepare a cutting jig to make outer pillar easier to cut. Also, this will permit service part to be accurately cut at joint position.

- An example of cutting operation using a cutting jig is as follows.

- Mark cutting lines.

- Cut position of outer pillar

- Cut position of inner pillar

- Align cutting line with notch on jig. Clamp jig to pillar.

- Cut outer pillar along groove of jig. (At position A)

- Remove jig and cut remaining portions.

- Cut inner pillar at position B in same manner.

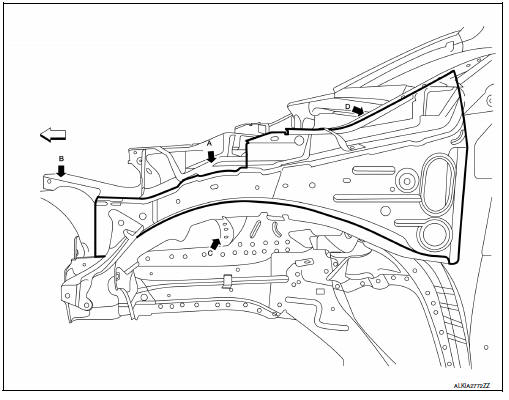

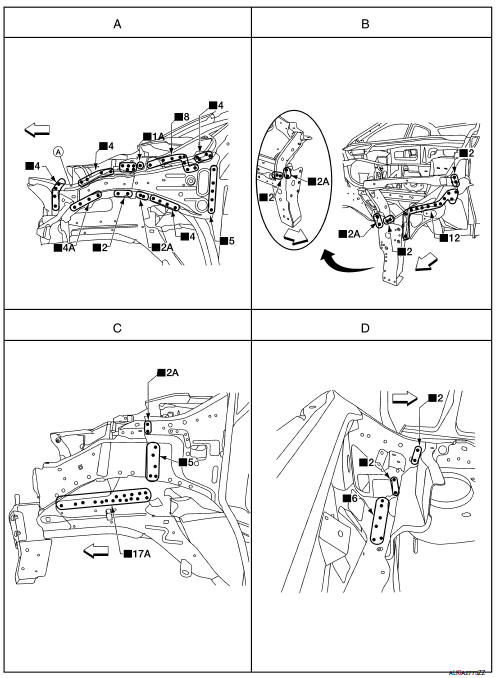

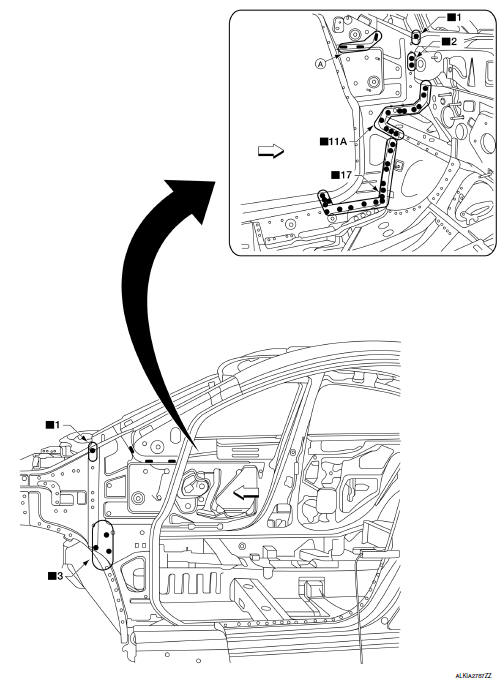

Hoodledge

Change parts

- Front hoodledge

- Radiator core support upper

- Front strut housing (LH)

- Hoodledge connector

Front

Front

Front Side Member

Change parts

- Front side member front assembly

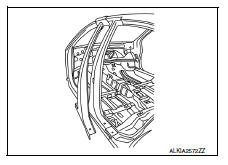

Front Pillar

OUTER

- Work after hoodledge and hoodledge reinforcement rear has been removed.

- Front pillar section of body side outer

- Recommended sectioning location

REINFORCEMENT

- Work after front pillar outer has been removed.

- Front pillar reinforcement

INNER

- Work after front pillar reinforcement has been removed.

- Front pillar inner reinforcement

- Stitch mig welds

Dash Side

Work with front pillar reinforcement removed.

- Dash side

- Stitch mig weld

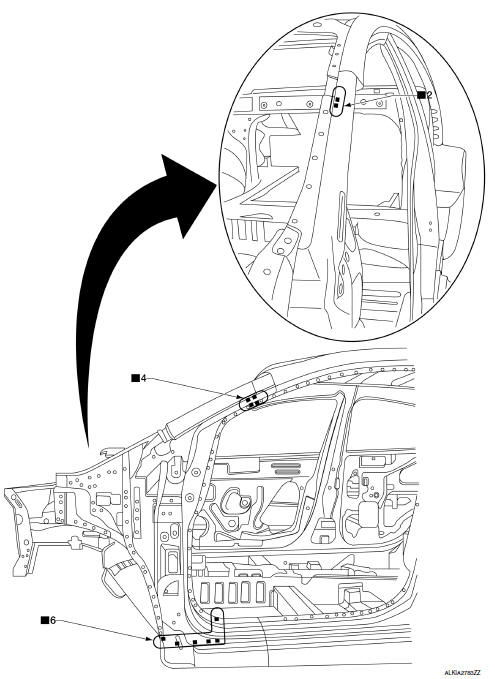

Center Pillar

OUTER

Change parts

- Center pillar portion of body side outer recommended sectioning area.

- 165 mm (6.5 in)

- 140 mm (5.5 in)

- 45 mm (1.8 in)

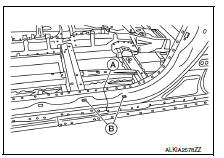

Removal

- Use a cut off wheel to make pre-measured cut in upper center pillar outer body side.

- Cut the sill area (A) between the sill plate holes (B) on the lower center pillar outer body side.

- Drill spot welds that attach the center pillar outer body side. Only drill through the outer panel.

- Remove the center pillar outer body side.

Installation

Match welds locations from removed part onto new panel and weld into place.

REINFORCEMENT

Work after center pillar outer has been removed.

- Center pillar reinforcement

Front

Front

Roof

- Roof panel

Front

Front

REMOVAL

- Remove the headlining. Refer to INT-40, "Removal and Installation".

- Remove the roof side moldings (RH/LH). Refer to EXT-32, "Removal and Installation".

- Remove the windshield glass. Refer to GW-12, "Removal and Installation".

- Remove the rear window glass. Refer to GW-26, "Removal and Installation".

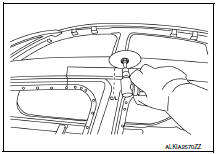

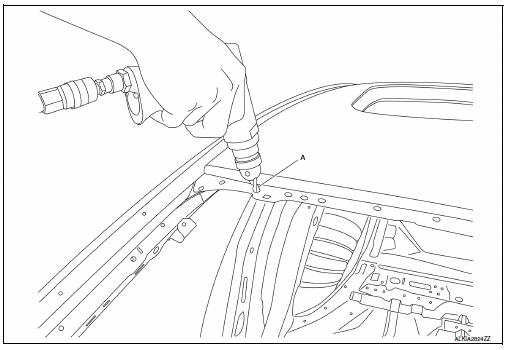

- Drill out spot welds using a 8.0 mm (0.31 in) spot weld removing bit (A) on the windshield and rear window glass flanges.

NOTE:

Only drill through the first layer of metal (the roof outer panel)

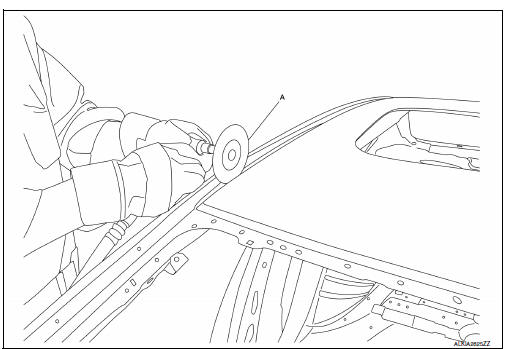

- Use an angle head grinder and a 3.18 mm (0.125 in) cutting wheel (A) to grind through the first layer only.

NOTE:

Only grind through the first layer of metal (the roof outer panel)

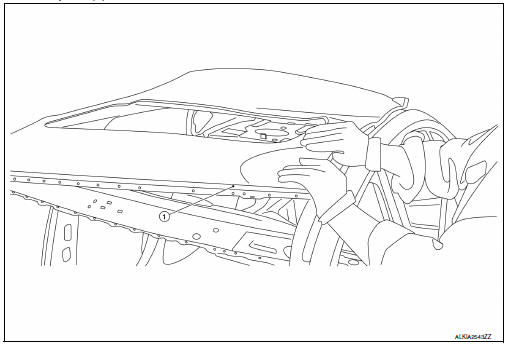

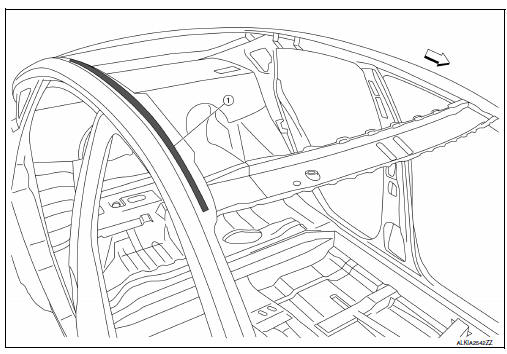

- Remove roof panel (1).

PREPARATION

- Weld through primer

Front

Front

- Grind all mating surfaces around the roof flanges.

- Test panel for proper alignment and fit.

- Remove panel.

- Compare to the removed panel, then drill 8.0 mm (0.31 in) holes in the same location on the new roof panel.

- Use 3M weld through primer to prime body side upper and the front and rear window flanges

INSTALLATION

- Body side upper spot welds

- Plug welds

- Clamping pliers

Front

Front

- Check the dimensions and fit.

- Use clamping pliers to retain the roof panel to the front and rear window flanges.

- Plug weld as necessary.

- Dress welds as necessary to allow proper glass fit.

- Refer to NISSAN approved panel refinishing

- Install the headlining. Refer to INT-40, "Removal and Installation".

- Install rear window glass. Refer to GW-26, "Removal and Installation".

- Install windshield glass. Refer to GW-12, "Removal and Installation".

- Install roof side moldings (RH/LH). Refer to EXT-32, "Removal and Installation".

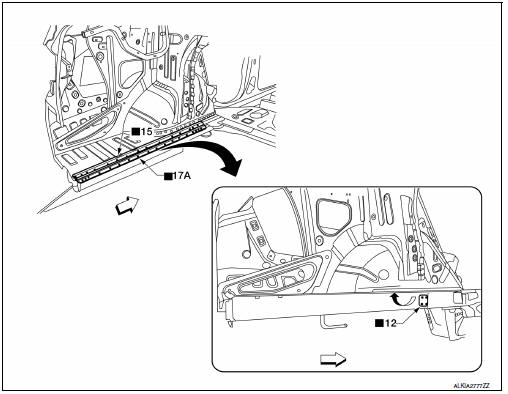

Outer Sill

Work after the front pillar reinforcement, center pillar reinforcement, and rear fender have been removed.

- Outer sill reinforcement

Front

Front

Rear Fender

- Recommended cut zone

- Bonded hem flange

Front

Front

Rear Panel

- Rear panel assembly

Rear Floor Rear

- Work after rear panel assembly has been removed.

- Rear floor rear

Rear Side Member Extension

- Work after rear panel assembly and rear floor rear have been removed.

- Rear side member extension

Front

Front

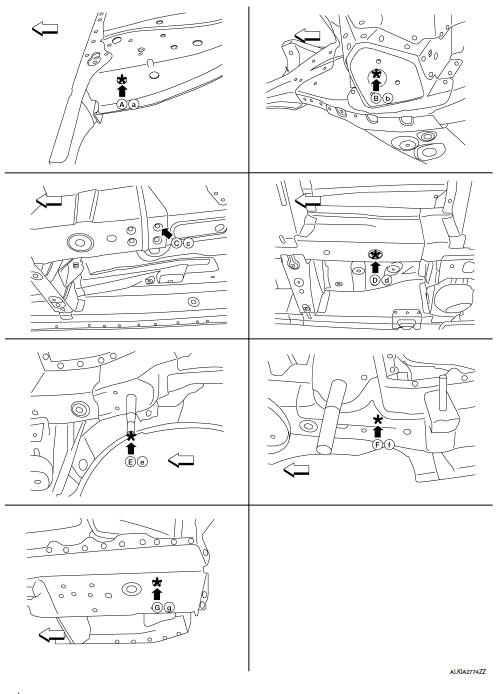

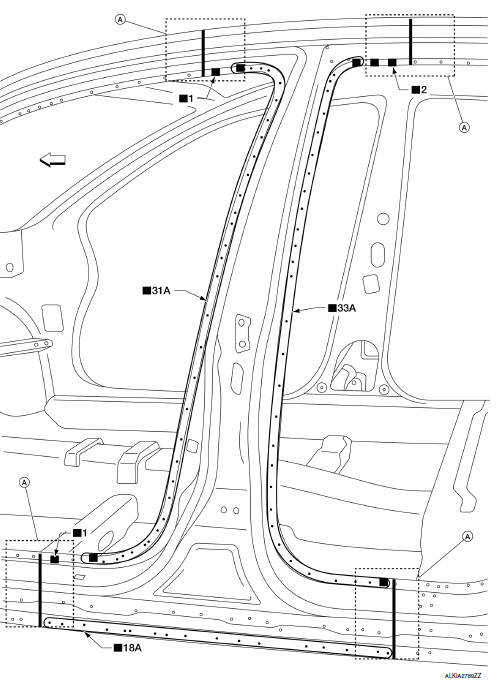

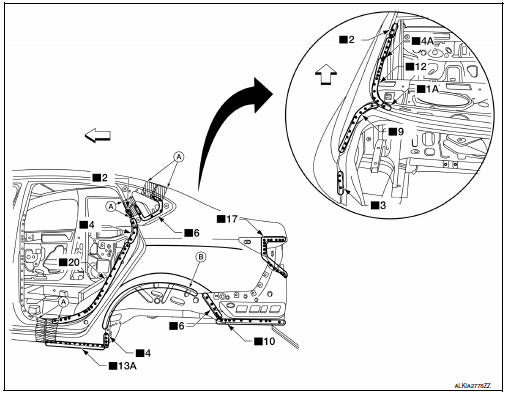

Body sealing

Body sealing

Description

The following figure shows the areas which are sealed at the factory. Sealant

which has been applied to these

areas should be smooth and free from cuts or gaps. Care should be taken no ...

Other materials:

Dtc/circuit diagnosis

Power supply and ground circuit

Audio unit

AUDIO UNIT : Diagnosis Procedure

Regarding wiring diagram information, refer to av-88, "wiring diagram".

1.Check fuse

Check that the following fuses are not blown.

Are the fuses blown?

Yes >> replace the blown fuse after repairing ...

Removal and installation

Nats antenna amp

Removal and installation

Removal

Remove instrument finisher b. Refer to ip-14, "exploded view".

Using a suitable tool release the pawls on either side and remove the

NATS antenna amp. from the pushbutton

ignition switch.

Installation

Installation is in the ...

Removal and installation

Av control unit

Exploded view

Av control unit

Av control unit bracket (lh)

Av control unit bracket (rh)

Removal and installation

Removal

Caution:

Remove battery terminal and av control unit after a lapse of 30

seconds or more after turning the

ignition switch off.

Befor ...