Nissan Sentra Service Manual: Rear shock absorber

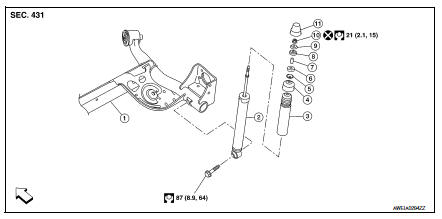

Exploded View

- Rear suspension beam

- Shock absorber

- Bound bumper

- Bound bumper cover

- Washer

- Bushing

- Distance tube

- Bushing

- Washer

- Piston rod lock nut

- Cap

Front

Front

Removal and Installation

REMOVAL

- Remove the rear shock tower access flap.

- Remove the cap from the rear shock absorber.

- Remove the piston rod lock nut (1).

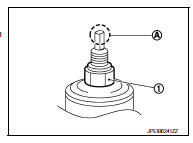

NOTE:

To loosen the piston rod lock nut, hold the tip (A) of the piston rod.

- Remove the washer and the bushing.

- Set a suitable jack under the rear suspension beam.

CAUTION:

- At this step, the jack must be set only for supporting the removal procedure. For details on jacking up the vehicle, refer to GI-31, "Garage Jack and Safety Stand and 2-Pole Lift".

- Do not damage the rear suspension beam with the jack.

- Make sure the rear suspension beam is stable when using the jack.

- Remove the lower shock absorber bolt.

- Remove the rear shock absorber.

- Remove the bushing, the distance tube, the washer, the bound bumper cover, and the bound bumper from the shock absorber.

- Inspect the components. Refer to RSU-10, "Inspection".

INSTALLATION

Installation is in the reverse order of removal.

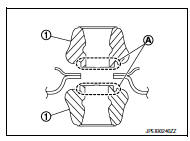

- To install the bushings (1), securely insert the protrusion (A) into the hole in the vehicle body.

- Install the washer (1) in the direction shown.

: Bushing side

: Bushing side

- Perform the final tightening of the bolts and nuts under unladen conditions with the tires on level ground.

- Hold the tip (A) of the piston rod. Tighten the piston rod lock nut (1) to the specification.

CAUTION:

Do not reuse the piston rod lock nut.

- When installing the cap, securely engage the cap groove (A) with the flange on the vehicle body.

- After replacing the shock absorber, always follow the disposal procedure

to discard the old shock absorber.

Refer to RSU-10, "Disposal".

Inspection

INSPECTION AFTER REMOVAL

Shock Absorber

Check the following items and replace the parts if necessary.

- Check the shock absorber for oil leaks, deformation, cracks, and other damage.

- Check the piston rod for damage, uneven wear, and distortion.

Bound Bumper, Bushing

Check for cracks and damage. Replace the parts if necessary.

Washer, Bound Bumper Cover, Distance Tube

- Check for cracks and damage. Replace the parts if necessary.

Disposal

- Set the shock absorber horizontally with the piston rod fully extended.

- Drill a 2 – 3 mm (0.08 – 0.12 in) hole at the position (

) from the top as shown to release gas gradually.

CAUTION:

- Wear eye protection (safety glasses).

- Wear gloves.

- Be careful with metal chips or oil blown out by the compressed gas.

NOTE:

- Drill vertically in this direction (

). - Drill directly to the outer tube avoiding brackets.

- The gas is clear, colorless, odorless, and harmless.

(A) : 20 – 30 mm (0.79 – 1.18 in)

- Position the drilled hole downward and drain oil by moving the piston rod several times.

CAUTION:

Dispose of drained oil according to the law and local regulations.

Coil spring

Coil spring

Exploded View

Upper rubber seat

Coil spring

Lower rubber seat

Rear suspension beam

Front

Removal and Installation

REMOVAL

Set a suitable jack under the rear suspension beam.

...

Other materials:

The door open warning continues displaying, or does not display

Description

The door ajar warning is displayed even though all of the doors are

closed.

The door ajar warning is not displayed even though a door is ajar.

Diagnosis procedure

1.Check bcm input signal

Check the bcm input signal. Refer to dlk-102, "component function check"

( ...

Periodic maintenance

M/T OIL

Inspection

OIL LEAKAGE

Make sure that gear oil is not leaking from transaxle or around it.

OIL LEVEL

Remove filler plug (1) and gasket from transaxle case.

Check the oil level from filler plug mounting hole as shown.

CAUTION:

Do not start engine while checking oil level.

Se ...

FM radio reception

Range: FM range is normally limited to 25 – 30 mi

(40 – 48 km), with monaural (single channel) FM

having slightly more range than stereo FM. External

influences may sometimes interfere with FM

station reception even if the FM station is within

25 mi (40 km). The strength of the FM signal is ...