Nissan Sentra Service Manual: Power window main switch

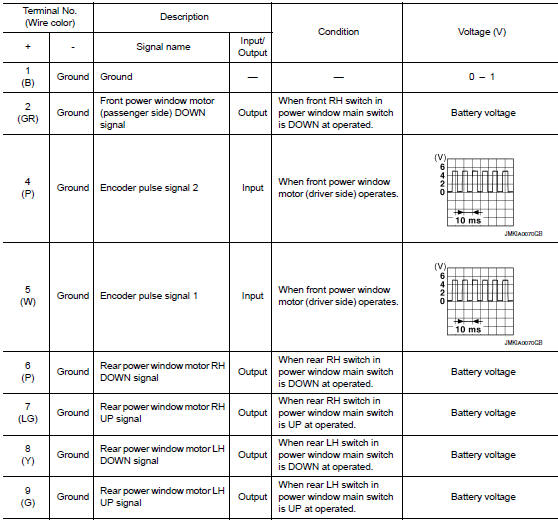

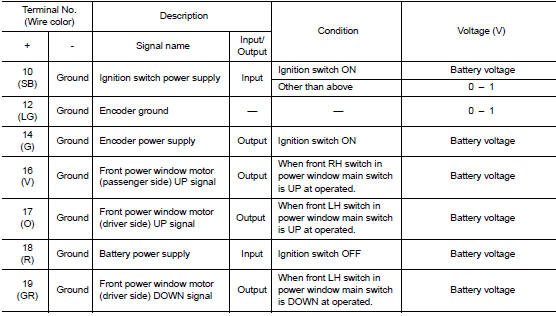

Reference Value

TERMINAL LAYOUT

PHYSICAL VALUES

MAIN POWER WINDOW AND DOOR LOCK/UNLOCK SWITCH

Fail Safe

FAIL-SAFE CONTROL

Switches to fail-safe control when malfunction is detected in encoder signal that detects up/down speed and direction of door glass. Switches to fail-safe control when error beyond regulation value is detected between the fully closed position and the actual position of the glass.

| Error | Error condition |

| Pulse sensor malfunction | When only one side of pulse signal is being detected for more than the specified value. |

| Both pulse sensors malfunction | When both pulse signals have not been detected for more than the specified value during glass open/close operation. |

| Pulse direction malfunction | When the pulse signal that is detected during glass open/close operation detects the opposite condition of power window motor operating direction. |

| Glass recognition position malfunction 1 | When it detects the error between glass fully closed position in power window switch memory and actual fully closed position during glass open/close operation is more than the specified value. |

| Glass recognition position malfunction 2 | When it detects pulse count more than the value of glass full stroke during glass open/close operation. |

It changes to condition before initialization and the following functions do not operate when switched to failsafe control.

- Auto-up operation

- Anti-pinch function

Perform initial operation to recover when switched to fail-safe mode. However, it switches back to fail-safe control when malfunction is found in power window main switch or front power window motor (driver side).

BCM(body control module)

BCM(body control module)

List of ECU Reference

WITH INTELLIGENT KEY SYSTEM

WITHOUT INTELLIGENT KEY SYSTEM

...

Wiring diagram

Wiring diagram

Power window system

Wiring Diagram

...

Other materials:

Component parts

Component parts location

Bcm (view with instrument panel removed)

Ipdm e/r (rear window defogger relay)

A/c auto amp. (View with a/c switch

assembly removed)

A/C switch assembly (rear window defogger

switch) (with auto A/C)

A/c switch assembly (rear window

defogger switch) (wit ...

General Precaution

WARNING:

When replacing fuel line parts, be sure to observe the following.

Put a “CAUTION: FLAMMABLE” sign in the work area.

Be sure to work in a well ventilated area and have a CO2 fire

extinguisher.

Do not smoke while working on the fuel system. Keep open flames

and sparks ...

P2096, P2097 A/F Sensor 1

DTC Logic

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible Cause

P2096

POST CAT FUEL TRIM SYS B1

(Post catalyst fuel trim system

too lean bank 1)

The output voltage computed by ECM from the

A/F ...