Nissan Sentra Service Manual: P0746 Pressure control solenoid A

DTC Logic

DTC DETECTION LOGIC

| DTC | CONSULT screen terms (Trouble diagnosis content) | DTC detection condition | Possible causes |

| P0746 | PRESSURE CONTROL SOLENOID A (Pressure Control Solenoid A Performance/Stuck Off) | The detecting condition A or detection condition

B is detected twice or more (1 second or

more later after detection of the first) in the

same DC under the following diagnosis conditions: Diagnosis conditions

Detection condition A

Detection condition B

|

|

NOTE:

DC stands for “DRIVING CYCLE” and indicates a series of driving cycle of “Ignition switch OFF → ON → driving → OFF”.

DTC CONFIRMATION PROCEDURE

CAUTION:

Be careful of the driving speed.

1.PREPARATION BEFORE WORK

If another “DTC CONFIRMATION PROCEDURE” occurs just before, turn ignition switch OFF and wait for at least 10 seconds, then perform the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

- Start the engine.

- Drive the vehicle.

- Maintain the following conditions for 10 seconds or more.

Selector lever : “D” position

Accelerator pedal position : 0.1/8 or more

Vehicle speed : 40 km/h (25 MPH) or more

- Stop the vehicle.

- Check the first trip DTC.

Is “P0746”detected? YES >> Go to TM-191, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK LINE PRESSURE SOLENOID VALVE

- Turn ignition switch OFF.

- Disconnect CVT unit connector.

- Check line pressure solenoid valve. Refer to TM-191, "Component Inspection"

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace malfunctioning parts.

2.CHECK LINE PRESSURE

Perform line pressure test. Refer to TM-149, "Work Procedure".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-39, "Intermittent Incident".

NO >> Repair or replace the malfunction items.

Component Inspection

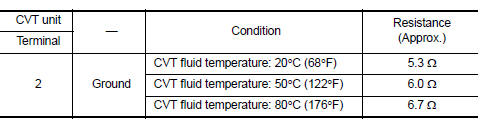

1.CHECK LINE PRESSURE SOLENOID VALVE

Check resistance between CVT unit connector terminal and ground.

Is the inspection

Is the inspection

result normal?

YES >> INSPECTION END

NO >> There is a malfunction of line pressure solenoid valve. Replace transaxle assembly. Refer to TM- 283, "Removal and Installation".

P0744 Torque converter

P0744 Torque converter

DTC Logic

DTC DETECTION LOGIC

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

Possible causes

P0744

TORQUE CONVERTER

(Torque converter ...

P0846 Transmission fluid pressure SEN/SW B

P0846 Transmission fluid pressure SEN/SW B

DTC Logic

DTC DETECTION LOGIC

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

Possible causes

P0846

TRANSMISSION FLUID

PRESSURE SEN/SW ...

Other materials:

System

Interior room lamp control system

INTERIOR ROOM LAMP CONTROL SYSTEM : System Diagram

WITH INTELLIGENT KEY

WITHOUT INTELLIGENT KEY

INTERIOR ROOM LAMP CONTROL SYSTEM : System Description

OUTLINE

Interior room lamp* is controlled by the interior room lamp timer

control function of t ...

P0447 EVAP Canister vent control valve

DTC Logic

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P0447

VENT CONTROL VALVE

(Evaporative emission system vent

control circuit open)

An improper voltage signal is sent to

ECM throug ...

FM/AM/SAT radio with compact disc (CD) player (Type A) (if so equipped)

For all operation precautions, see “Audio operation

precautions” in this section.

Audio main operation

VOL (volume) knob / PWR (power) button:

Place the ignition switch in the ACC or ON

position and press the VOL (volume) knob /PWR

(power) button while the system is off to call up

the mod ...