Nissan Sentra Service Manual: Oil seal

Valve oil seal : Removal and Installation

REMOVAL

- Rotate crankshaft, and set piston whose valve oil seal is to be removed to TDC. This will prevent valve from dropping into cylinder.

CAUTION:

When rotating crankshaft, be careful to avoid scarring front cover with timing chain.

- Remove camshafts. Refer to EM-60, "Exploded View".

- Remove valve lifters. Refer to EM-60, "Exploded View".

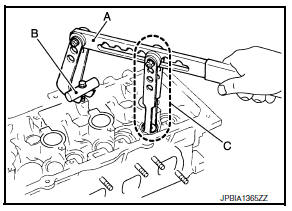

- Remove valve collet, valve spring retainer, and valve spring using Tools

Tool number (A) : KV1016200 (J-26336-A)

Tool number (B) : KV10109220 ( — )

Tool number (C) : KV10115900 (J-26336-20)

CAUTION:

- Do not damage valve lifter holes.

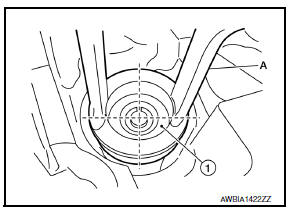

- Install Tool (A) in the center of valve spring retainer to press it.

(1) : Valve spring retainer

(A) : Attachment

Tool number : KV10115900 (J-26336-20)

- Remove valve spring retainer and valve spring (with valve spring seat).

CAUTION:

Do not remove valve spring seat from valve spring.

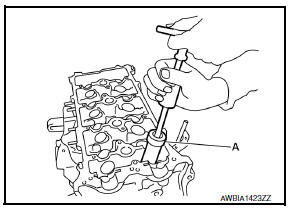

- Remove valve oil seal using Tool (A).

Tool number : KV10107902 (J-38959)

INSTALLATION

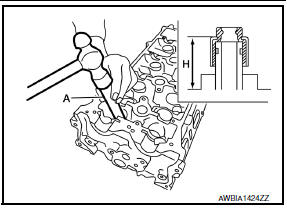

- Apply new engine oil to valve oil seal joint surface and seal lip.

- Press in valve oil seal to the height (H) shown using Tool (A).

Height (H) : 15.1 - 15.7 mm (0.594 - 0.618 in)

Tool number : KV10115600 (J-38958)

- Installation of remaining components is in the reverse order of removal.

Front oil seal : Removal and Installation

REMOVAL

- Remove front fender protector (RH). Refer to EXT-27, "FENDER PROTECTOR : Exploded View".

- Remove drive belt. Refer to EM-15, "Exploded View".

- Remove crankshaft pulley. Refer to EM-48, "Exploded View".

- Remove front oil seal using suitable tool.

CAUTION:

Do not damage front cover and crankshaft.

INSTALLATION

- Apply new engine oil to new front oil seal joint surface and seal lip.

- Install front oil seal so that each seal lip is oriented as shown.

(A) : Dust seal lip

(B) : Oil seal lip

- Press-fit front oil seal using a suitable tool with outer diameter 57 mm (2.24 in) and inner diameter 45 mm (1.77 in).

Within 0.3 mm (0.012 in) toward engine front (crankshaft pulley side)

Within 0.5 mm (0.020 in) toward engine rear (crankshaft sprocket side)

CAUTION:

- Be careful not to damage front cover and crankshaft.

- Press-fit oil seal straight to avoid causing burrs or tilting.

- Installation of remaining components is in the reverse order of removal.

Rear oil seal : Removal and Installation

REMOVAL

- Remove engine and transaxle assembly. Refer to EM-86, "CVT : Exploded View" (CVT models) or TM-28, "Exploded View" (M/T models).

- Remove clutch cover and clutch disc (M/T models). Refer to CL-17, "Exploded View".

- Remove drive plate (CVT models) or flywheel (M/T models). Refer to EM-94, "Exploded View".

- Remove rear oil seal using suitable tool.

CAUTION:

Do not damage crankshaft and cylinder block.

INSTALLATION

- Apply the liquid gasket lightly to entire outside area of new rear oil

seal.

Use Genuine Silicone RTV Sealant, or equivalent. Refer to GI-21, "Recommended Chemical Products and Sealants".

- Install rear oil seal so that each seal lip is oriented as shown.

(A) : Dust seal lip

(B) : Oil seal lip

- Press-fit rear oil seal using suitable tool (A) with outer diameter 115 mm (4.53 in) and inner diameter 90 mm (3.54 in).

CAUTION:

- Do not damage crankshaft and cylinder block.

- Press-fit oil seal straight to avoid causing burrs or tilting.

- Do not touch grease applied onto oil seal lip.

- Press in rear oil seal (1) to the position as shown.

(A) : Rear end surface of cylinder block

- Installation of the remaining components is in the reverse order of removal

Camshaft

Camshaft

Exploded View

Camshaft position sensor (EXH)

O-ring

Camshaft bracket

Camshaft (EXH)

Camshaft sprocket (EXH)

Camshaft sprocket (INT)

Camshaft (INT)

Valve lifter (EXH)

Valve lif ...

Cylinder head

Cylinder head

Exploded View

Cylinder head assembly

Cylinder head bolt

Cylinder head gasket

Refer to INSTALLATION

Removal and Installation

REMOVAL

Release fuel pressure. Refer to EC-143, ...

Other materials:

Folding rear seat

Pull the knob A to fold each seatback down.

WARNING

Never allow anyone to ride in the cargo

area or on the rear seat when it is in the

fold-down position. Use of these areas

by passengers without proper restraints

could result in serious injury in an accident

or s ...

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT

BELT PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver and front passenger for certain

types of collision. Information necessary to service the system ...

Dlc branch line circuit

Diagnosis procedure

1.Check connector

Turn the ignition switch OFF.

Disconnect the battery cable from the negative terminal.

Check the terminals and connectors of the data link connector for

damage, bend and loose connection

(connector side and harness side).

Is the inspection resul ...