Nissan Sentra Service Manual: Main line between ipdm-e and dlc circuit

Diagnosis procedure

1.Check connector

- Turn the ignition switch off.

- Disconnect the battery cable from the negative terminal.

- Check the following terminals and connectors for damage, bend and loose connection (connector side and harness side).

- Harness connector e4

- Harness connector m2

Is the inspection result normal? Yes >> go to 2.

No >> repair the terminal and connector.

2.Check harness continuity (open circuit)

- Disconnect the following harness connectors.

- Ipdm e/r

- Harness connectors e4 and m2

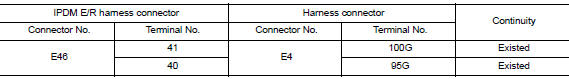

- Check the continuity between the ipdm e/r harness connector and the harness connector.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair the main line between the IPDM E/R and the harness connector E4.

3.Check harness continuity (open circuit)

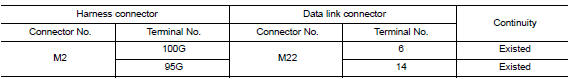

Check the continuity between the harness connector and the data link connector.

Is the inspection result normal? Yes (present error)>>check can system type decision again.

Yes (past error)>>error was detected in the main line between the ipdm e/r and the data link connector.

No >> repair the main line between the harness connector m2 and the data link connector.

Can system (type 2)

Can system (type 2)

Dtc/circuit diagnosis ...

Ecm branch line circuit

Ecm branch line circuit

Diagnosis procedure

1.Check connector

Turn the ignition switch off.

Disconnect the battery cable from the negative terminal.

Check the terminals and connectors of the ecm for damage, bend and ...

Other materials:

Power window motor

DRIVER SIDE

DRIVER SIDE : Description

Door glass moves up/down by receiving the signal from main power window and

door lock/unlock switch

DRIVER SIDE : Component Function Check

1. Check front power window motor lh circuit

Check front power window motor lh operation with the main power window ...

Refrigerant pressure sensor

Component Function Check

1.CHECK REFRIGERANT PRESSURE SENSOR OVERALL FUNCTION

Start engine and warm it up to normal operating temperature.

Turn A/C switch and blower fan switch ON.

Check the voltage between ECM harness connector terminals.

Is the inspection result normal?

YES >> ...

Abbreviations

Abbreviation List

The following ABBREVIATIONS are used:

A

ABBREVIATION

DESCRIPTION

A/C

Air conditioner

A/C

Air conditioning

A/F sensor

Air fuel ratio sensor

A/T

Automatic transaxle/transmission

ABS

Anti-lock braking sys ...