Nissan Sentra Service Manual: Liquid Gasket

REMOVAL OF LIQUID GASKET SEALING

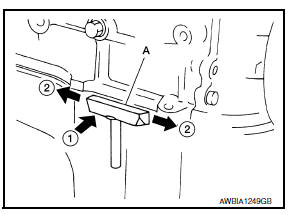

- After removing the bolts and nuts, separate the mating surface and remove the liquid gasket using Tool (A).

Tool Number : KV10111100 (J-37228)

CAUTION:

Be careful not to damage the mating surfaces.

- In areas where the cutter is difficult to use, use a plastic hammer to lightly tap (1) the cutter where the liquid gasket is applied. Use a plastic hammer to slide (2) the cutter by tapping on the side.

CAUTION:

Do not damage the mating surfaces.

LIQUID GASKET APPLICATION PROCEDURE

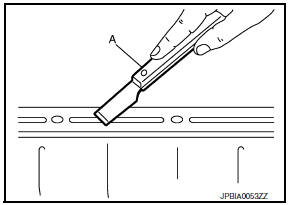

- Using suitable tool (A), remove old liquid gasket adhering to the liquid gasket application surface and the mating surface.

- Remove liquid gasket completely from the groove of the liquid gasket application surface, mounting bolts, and bolt holes.

- Wipe the liquid gasket application surface and the mating surface with white gasoline (lighting and heating use) to remove adhering moisture, grease and foreign materials.

- Attach liquid gasket tube to the suitable tool.

Use Genuine Silicone RTV Sealant, or equivalent. Refer to GI-21, "Recommended Chemical Products and Sealants".

- Apply liquid gasket without gaps to the specified location according to the specified dimensions.

- If there is a groove for liquid gasket application, apply liquid gasket to the groove.

- As for bolt holes (B), normally apply liquid gasket inside the

holes. Occasionally, it should be applied outside the holes.

Check to read the text of this manual.

(A) : Groov

Inside

Inside

- Within five minutes of liquid gasket application, install the mating component.

- If liquid gasket protrudes, wipe it off immediately.

- Do not retighten mounting bolts or nuts after the installation.

- After 30 minutes or more have passed from the installation, fill engine oil and engine coolant.

CAUTION:

If there are specific instructions in the procedures contained in this manual concerning liquid gasket application, observe them.

Parts Requiring Angle Tightening

Parts Requiring Angle Tightening

Use the Tool for the final tightening of the following engine parts:

Tool number : KV10112100 (BT-8653-A)

Camshaft sprocket (INT) bolt

Cylinder head bolts

Main bearing cap bolts

Connec ...

Preparation

Preparation

...

Other materials:

Steering wheel

Inspection

CONDITION OF INSTALLATION

Check installation condition of power steering gear

assembly, front suspension, front drive shaft and steering

column.

Check if movement exists when steering wheel is moved up and

down, to the left and right and to the axial

direction.

S ...

Wheel alignment

Inspection

DESCRIPTION

Measure the wheel alignment under unladen conditions.

NOTE:

“Unladen conditions” means that fuel, engine coolant, and lubricants are

full. Spare tire, jack, hand tools and

mats are in designated positions.

PRELIMINARY

Check the following:

Tires for impro ...

Diagnosis system (ipdm e/r) (with intelligent key system)

Diagnosis Description

AUTO ACTIVE TEST

Description

In auto active test, the IPDM E/R sends a drive signal to the following

systems to check their operation.

Front wiper (LO, HI)

Parking lamp

License plate lamp

Tail lamp

Front fog lamp (if equipped)

Headlamp (LO, HI)

A/C compres ...