Nissan Sentra Service Manual: Evaporative emission system

EVAPORATIVE EMISSION SYSTEM : System Description

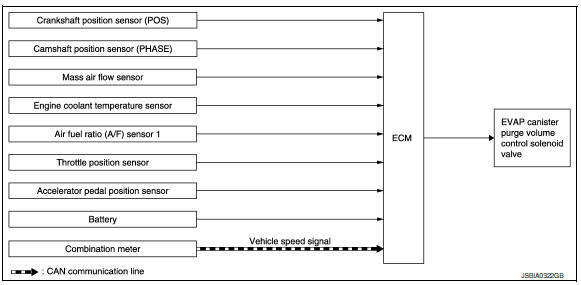

SYSTEM DIAGRAM

INPUT/OUTPUT SIGNAL CHART

| Sensor | Input signal to ECM | ECM function | Actuator | |

| Crankshaft position sensor (POS) | Engine speed* | EVAP canister purge flow control | EVAP canister purge volume control solenoid valve | |

| Camshaft position sensor (PHASE) | ||||

| Mass air flow sensor | Amount of intake air | |||

| Engine coolant temperature sensor | Engine coolant temperature | |||

| Air fuel ratio (A/F) sensor 1 | Density of oxygen in exhaust gas (Mixture ratio feedback signal) | |||

| Throttle position sensor | Throttle position | |||

| Accelerator pedal position sensor | Accelerator pedal position | |||

| Battery | Battery voltage* | |||

| Combination meter | CAN communication | Vehicle speed signal | ||

*: ECM determines the start signal status by the signals of engine speed and battery voltage.

SYSTEM DESCRIPTION

The evaporative emission system is used to reduce hydrocarbons emitted into the atmosphere from the fuel system. This reduction of hydrocarbons is accomplished by activated charcoals in the EVAP canister.

The fuel vapor in the sealed fuel tank is led into the EVAP canister which contains activated carbon and the vapor is stored there when the engine is not operating or when refueling to the fuel tank.

The vapor in the EVAP canister is purged by the air through the purge line to the intake manifold when the engine is operating. EVAP canister purge volume control solenoid valve is controlled by ECM. When the engine operates, the flow rate of vapor controlled by EVAP canister purge volume control solenoid valve is proportionally regulated as the air flow increases.

EVAP canister purge volume control solenoid valve also shuts off the vapor purge line during decelerating and idling.

Starter motor drive control

Starter motor drive control

STARTER MOTOR DRIVE CONTROL : System Description

SYSTEN DIAGRAM

*1: CVT models

*2: M/T models

INPUT/OUTPUT SIGNAL CHART

Sensor

Input signal to ECM

ECM function

Actuator

...

Automatic speed control device (ASCD)

Automatic speed control device (ASCD)

AUTOMATIC SPEED CONTROL DEVICE (ASCD) : System Description

SYSTEM DIAGRAM

BASIC ASCD SYSTEM

Refer to Owner's Manual for ASCD operating instructions.

Automatic Speed Control Device (ASCD) all ...

Other materials:

Precaution for Liquid Gasket

Removal of liquid gasket

After removing the bolts and nuts, separate the mating surface and

remove the old liquid gasket using tool.

Tool number : kv10111100 (j-37228)

Caution:

Do not damage the mating surfaces.

Tap the seal cutter to insert it (1).

In areas where the tool is diffic ...

Shift lock system

Component Function Check

1.CHECK SHIFT LOCK OPERATION (PART 1)

Turn ignition switch ON.

Shift the selector lever to park “P” position.

Attempt to shift the selector lever to any other position with the brake

pedal released.

Can the selector lever be shifted to any other posi ...

The seat belt reminder warning

continues sounding, or does not

sound

Description

Seat belt reminder warning does not sound.

Seat belt reminder warning sounds continuously.

Diagnosis procedure

1.Check seat belt warning lamp

Turn ignition switch on.

Check the operation of the seat belt warning lamp in the combination

meter.

Is the inspection ...