Nissan Sentra Service Manual: Electrical load signal

Description

The electrical load signal (Headlamp switch signal, rear window defogger switch signal, etc.) is transferred via the CAN communication line.

Component Function Check

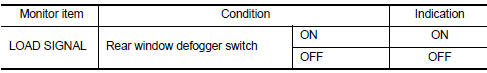

1.CHECK REAR WINDOW DEFOGGER SWITCH FUNCTION

With CONSULT

With CONSULT

- Turn ignition switch ON.

- Select “DATA MONITOR” mode of “ENGINE” using CONSULT.

- Select “LOAD SIGNAL” and check indication as per the following conditions.

Is the inspection result normal? YES >> GO TO 2.

NO >> Proceed to EC-461, "Diagnosis Procedure".

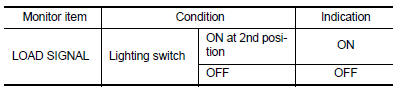

2.CHECK LIGHTING SWITCH FUNCTION

With CONSULT

With CONSULT

Check “LOAD SIGNAL” indication as per the following conditions.

Is the inspection result normal? YES >> GO TO 3.

NO >> Proceed to EC-461, "Diagnosis Procedure".

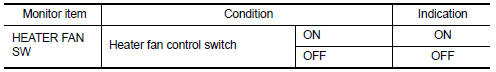

3.CHECK HEATER FAN CONTROL SWITCH FUNCTION

With CONSULT

With CONSULT

Select “HEATER FAN SW” and check indication as per the following conditions.

Is the inspection result normal? YES >> INSPECTION END

NO >> Proceed to EC-461, "Diagnosis Procedure".

Diagnosis Procedure

1.INSPECTION START

Confirm the malfunctioning circuit (rear window defogger, headlamp or heater fan). Refer to EC-461, "Component Function Check".

Which circuit is related to the incident? Rear window defogger>>GO TO 2.

Headlamp>>GO TO 3.

Heater fan>>GO TO 4.

2.CHECK REAR WINDOW DEFOGGER SYSTEM

Check the rear window defogger system. Refer to DEF-27, "Work Flow".

>> INSPECTION END

3.CHECK HEADLAMP SYSTEM

Check the headlamp system. Refer to EXL-85, "Work Flow".

>> INSPECTION END

4.CHECK HEATER FAN CONTROL SYSTEM

Check the heater fan control system. Refer to HA-15, "Workflow".

>> INSPECTION END

Ignition signal

Ignition signal

Component Function Check

1.INSPECTION START

Turn ignition switch OFF.

Start engine.

Does the engine start?

YES >> GO TO 2.

NO >> Proceed to EC-456, "Diagnosis Procedure& ...

Cooling fan

Cooling fan

Component Function Check

1.CHECK COOLING FAN FUNCTION

With CONSULT

Turn ignition switch ON.

Perform “FAN” in “ACTIVE TEST” mode of “ENGINE” using CONSULT

Check ...

Other materials:

Windshield wiper and washer switch

Switch operation

Type A

Type B

The windshield wiper and washer operates when

the ignition switch is placed in the ON position.

Push the lever down to operate the wiper at the

following speed:

Intermittent (INT) — intermittent operation

can be adjusted by turning the knob A .

Lo ...

Engine assembly CVT

CVT : Exploded View

Washer

Upper torque rod (RH)

Engine mounting insulator (RH)

Engine mounting insulator (LH)

Rear torque rod bracket

Rear torque rod

CVT : Removal and Installation

WARNING:

Situate the vehicle on a flat and solid surface.

Place chocks at front and back o ...

Rear seat

Exploded View

Rear seatback assembly (RH)

Seatback striker

Seatback latch release knob

Seatback latch assembly

Seatback silencer (RH)

Rear seatback frame (RH)

Seatback latch release knob finisher

Rear seat bolster trim (RH)

Rear seat bolster pad (RH)

Rear seat bolster (RH)

...