Nissan Sentra Service Manual: Diagnosis and repair workflow

Work flow

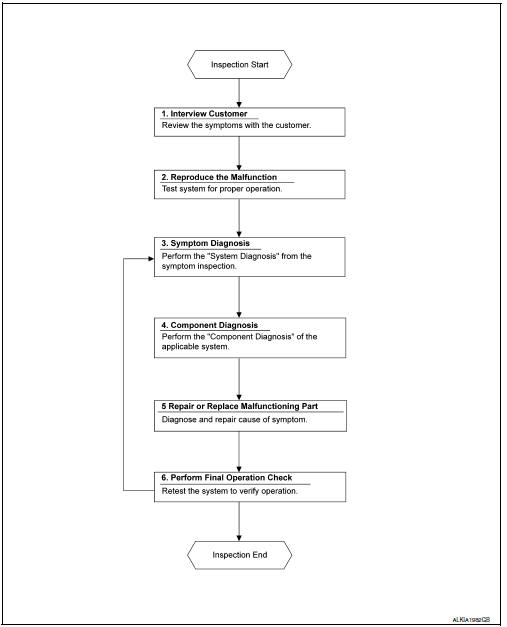

Overall sequence

Detailed flow

1. Obtain information about symptom

Interview the customer to obtain as much information as possible about the conditions and environment under which the malfunction occurred.

>> GO TO 2.

2. Confirm concern

Check the malfunction on the vehicle that the customer describes.

Inspect the relation of the symptoms and the condition when the symptoms occur.

>> Go to 3.

3. Identify the malfunctioning system with symptom diagnosis

Use Symptom diagnosis from the symptom inspection result in step 2 and then identify where to start performing the diagnosis based on possible causes and symptoms.

>> GO TO 4.

4. Perform the component diagnosis of the applicable system

Perform the diagnosis with Component diagnosis of the applicable system.

>> GO TO 5.

5. Repair or replace the malfunctioning parts

Repair or replace the specified malfunctioning parts.

>> Go to 6.

6. Final check

Check that malfunctions are not reproduced when obtaining the malfunction information from the customer, referring to the symptom inspection result in step 2.

Are the malfunctions corrected? Yes >> inspection end.

No >> go to 3.

Basic inspection

Basic inspection

...

Inspection and adjustment

Inspection and adjustment

Additional service when replacing control unit

Additional service when replacing control unit : description

Memory reset procedure

Please observe the following instructions at confirming the moo ...

Other materials:

P0111 IAT Sensor

DTC Logic

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P0111

IAT SENSOR 1 B1

(Intake air temperature sensor 1

circuit range/performance bank 1)

The comparison result of signals transmitte ...

Basic inspection

Work Procedure

1.INSPECTION START

Check service records for any recent repairs that may indicate a related

malfunction, or a current need for

scheduled maintenance.

Open engine hood and check the following:

Harness connectors for improper connections

Wiring harness for improper c ...

Washer nozzle & tube

Exploded view

Check valve

Washer tube

Washer tank

Washer pump

Washer nozzle

Clip

Washer nozzle

Washer nozzle : removal and installation

REMOVAL

Disconnect the washer nozzle from the hood by pushing on the

nozzle in the order and direction shown.

Disconnect the ...