Nissan Sentra Service Manual: Clutch disc and clutch cover

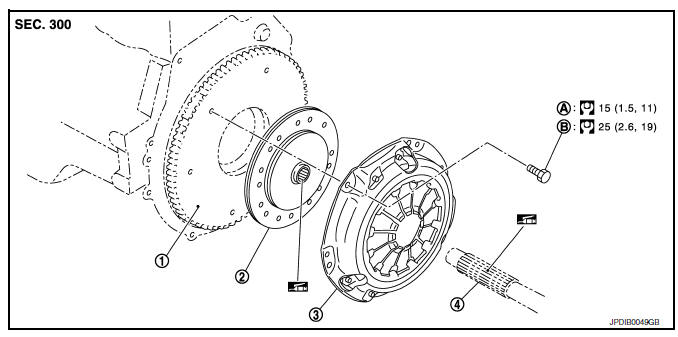

Exploded View

- Flywheel

- Clutch disc

- Clutch cover

- Input shaft

- First step

- Final step

Apply lithium-based grease

Apply lithium-based grease

including molybdenum disulphide.

Removal and Installation

CAUTION:

- Do not reuse CSC (Concentric Slave Cylinder). The CSC slides back

to the original position every

time the transaxle assembly is removed. This action may allow dust or

contaminants to gather on

the sliding parts and damage a seal of CSC causing clutch fluid leakage.

Refer to CL-16, "Removal and Installation".

- Do not allow any grease to contact the clutch disc facing, pressure plate surface or flywheel surface.

- Do not clean clutch disc using solvent.

REMOVAL

- Remove engine and transaxle assembly. Refer to TM-28, "Removal and Installation".

- Loosen clutch cover bolts evenly while holding clutch cover.

- Remove clutch cover and clutch disc.

CAUTION:

Do not drop clutch disc.

INSTALLATION

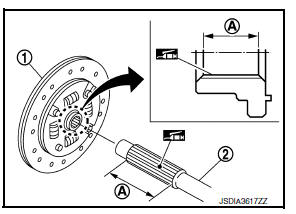

- Clean clutch disc and input shaft splines to remove grease and dust caused by abrasion.

- Apply recommended grease to clutch disc (1) and input shaft (2) splines area (A).

CAUTION:

Be sure to apply grease to the points specified. Otherwise, noise, poor disengagement, or damage to the clutch may result. Excessive grease may cause slip or shudder. And if it adheres to seal of CSC, it may cause clutch fluid leakage.

Wipe off excess grease. Wipe off any grease oozing from the parts.

- Install clutch disc, using a suitable tool (A).

- Install clutch cover, and then temporarily tighten clutch cover bolts.

- Tighten clutch cover bolts to the specified torque evenly in two steps in the numerical order as shown.

- Install engine and transaxle assembly. Refer to TM-28, "Removal and Installation".

Inspection

INSPECTION AFTER REMOVAL

Clutch Disc

- Measure clutch facing runout. If it is outside the specification, replace clutch disc.

Runout limit/diameter of the area to be measured : Refer to CL-20, "Clutch Disc".

- Measure spline backlash at outer edge of clutch disc. If it is outside the specification, replace clutch disc.

Maximum allowable spline backlash (at outer edge of disc) : Refer to CL-20, "Clutch Disc".

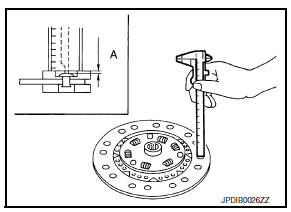

- Measure the depth “A) to clutch disc facing rivet heads, using suitable tool. If it exceeds the allowable wear limit, replace clutch disc.

Facing wear limit (depth to the rivet head) “A” : Refer to CL-20, "Clutch Disc".

Clutch Cover

- Check clutch cover thrust ring for wear or damage. If wear or damage is found, replace clutch cover.

NOTE:

- Worn thrust ring will generate a beating noise when tapped at the rivet using suitable tool

- Broken thrust ring will make a clinking sound when cover is shaken up and down.

- If a trace of burn or discoloration is found on the clutch cover pressure plate to clutch disc contact surface, repair the surface with sandpaper. If surface is damaged or distorted, replace clutch cover.

INSPECTION AFTER INSTALLATION

Clutch Cover

Check diaphragm spring lever claws for unevenness with the clutch cover installed on the engine. If they exceed the tolerance, adjust diaphragm spring lever using Tool (A).

Tolerance for diaphragm spring lever unevenness : Refer to CL-20, "Clutch Cover".

Tool number : ST20050240 ( — )

CSC(concentric slave cylinder)

CSC(concentric slave cylinder)

Exploded View

Transaxle assembly

CSC (Concentric Slave Cylinder)

Removal and Installation

CAUTION:

Do not reuse CSC (Concentric Slave Cylinder). The CSC slides back

to the origina ...

Service data and specifications (SDS)

Service data and specifications (SDS)

General Specifications

Clutch Pedal

Clutch Disc

Clutch Cover

...

Other materials:

Steering column

Inspection

STEERING COLUMN ASSEMBLY

Check each part of steering column assembly for damage or

other malfunctions. Replace entire steering column

assembly if any parts are damaged.

Measure steering column rotating torque using Tool. Replace

steering column assembly if outside the ...

Refrigerant pressure sensor

Component Function Check

1.CHECK REFRIGERANT PRESSURE SENSOR OVERALL FUNCTION

Start engine and warm it up to normal operating temperature.

Turn A/C switch and blower fan switch ON.

Check the voltage between ECM harness connector terminals.

Is the inspection result normal?

YES >> ...

Compression pressure

Inspection

Warm up the engine to full operating temperature.

Release fuel pressure. Refer to EC-143, "Work Procedure".

Remove ignition coil and spark plug from each cylinder. Refer to EM-46,

"Exploded View".

Connect engine tachometer (not required in use of CONSULT). ...