Nissan Sentra Service Manual: C1164, C1165, C1166, C1167 CV/SV System

DTC Logic

Dtc detection logic

| DTC | Display Item | Malfunction detected condition | Possible causes |

| C1164 | CV 1 | When a malfunction is detected in cut valve 1. |

|

| C1165 | CV 2 | When a malfunction is detected in cut valve 2. | |

| C1166 | SV 1 | When a malfunction is detected in suction valve 1. | |

| C1167 | SV 2 | When a malfunction is detected in suction valve 2. |

DTC CONFIRMATION PROCEDURE

1.CHECK SELF DIAGNOSTIC RESULT

With CONSULT.

With CONSULT.

-

Turn ignition switch OFF to ON.

-

Perform self diagnostic result.

Is DTC C1164, C1165, C1166 or C1167 detected? YES >> Proceed to diagnosis procedure. Refer to BRC-85, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis Procedure

Regarding Wiring Diagram information, refer to BRC-44, "Wiring Diagram".

1.CONNECTOR INSPECTION

-

Turn ignition switch OFF.

-

Disconnect ABS actuator and electric unit (control unit) connector.

-

Check connector and terminals for deformation, disconnection, looseness or damage.

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace as necessary.

2.Check abs actuator and electric unit (control unit) battery power supply

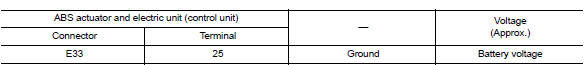

Check voltage between ABS actuator and electric unit (control unit) connector E33 terminal 25 and ground.

Is the inspection result normal? Yes >> go to 3.

No >> repair or replace malfunctioning components.

3.Check abs actuator and electric unit (control unit) ground circuit

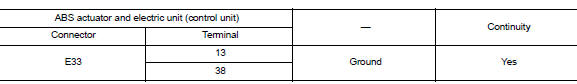

Check continuity between abs actuator and electric unit (control unit) connector e33 terminals 13, 38 and ground.

Is the inspection result normal? Yes >> replace abs actuator and electric unit (control unit). Refer to brc-110, "removal and installation".

No >> repair or replace malfunctioning components.

C1155 BR Fluid level low

C1155 BR Fluid level low

DTC Logic

Dtc detection logic

Dtc

Display item

Malfunction detected condition

Possible cause

C1155

C1155 br fluid level low

Brake fluid level is low or communication l ...

U1000 CAN Comm circuit

U1000 CAN Comm circuit

DTC Logic

DTC DETECTION LOGIC

DTC

Display Item

Malfunction detected condition

Possible causes

U1000

CAN COMM CIRCUIT

When CAN communication signal is not continuously

...

Other materials:

C1140 Actuator relay system

DTC Logic

DTC DETECTION LOGIC

DTC

Display Item

Malfunction detected condition

Possible causes

C1140

ACTUATOR RLY

When a malfunction is detected in actuator relay.

Harness or connector

ABS actuator and electric unit

(control unit)

Fusible link ...

B2267 engine speed

Description

The engine speed signal is transmitted from ecm to the combination meter via

can communication.

Dtc logic

Dtc detection logic

Dtc

Consult

Detection condition

Possible malfunction location

B2267

Tacho meter

[b2267]

ECM continuously transmits abnorma ...

Steering column

Exploded View

Steering column assembly

Slide plates

lower shaft assembly

Removal and Installation

REMOVAL

CAUTION:

While removing the steering column assembly, do not

unlock the tilt lever.

Do not impact on the axis when removing steering

column assembly.

...