Nissan Sentra Service Manual: Basic inspection

Diagnosis and repair workflow

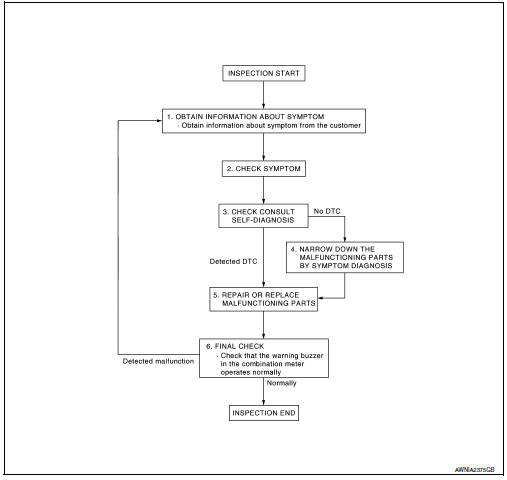

Work flow

Overall sequence

Detailed flow

1.Obtain information about symptom

Interview the customer to obtain as much information as possible about the conditions and environment under which the malfunction occurred.

>> GO TO 2.

2.Check symptom

- Check the symptom based on the information obtained from the customer.

- Check if any other malfunctions are present.

>> Go to 3.

3.Check consult self-diagnosis results

Connect consult and perform self-diagnosis. Refer to mwi-26, "dtc index".

Are self-diagnosis results normal? Yes >> go to 4.

No >> go to 5.

4.Narrow down malfunctioning parts by symptom diagnosis

Perform symptom diagnosis and narrow down the malfunctioning parts.

>> Go to 5.

5.Repair or replace malfunctioning parts

Repair or replace malfunctioning parts.

Note:

If dtc is displayed, erase dtc after repairing or replacing malfunctioning parts.

>> Go to 6.

6.Final check

Check that the warning buzzer in the combination meter operates normally.

Does it operate normally? Yes >> inspection end.

No >> go to 1.

Wiring diagram

Wiring diagram

Meter system

Wiring diagram

Compass

Wiring diagram

...

Other materials:

System description

Component parts

Component parts location

Ipdm e/r (contains ignition relay-1)

Bcm (view with instrument panel removed)

Fuse block (j/b) (front)

Fuse block (j/b) (back)

Blower relay

Ignition relay-2

Accessory relay-1

Push-button ignition switch

Component description

...

P0130 A/F Sensor 1

DTC Logic

DTC DETECTION LOGIC

To judge the malfunction, the diagnosis checks that the A/F signal computed

by ECM from the A/F sensor 1

signal fluctuates according to fuel feedback control.

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possi ...

Removal and installation

Audio unit

Exploded view

Audio unit

Audio unit bracket (LH)

Audio unit bracket (rh)

Removal and installation

Removal

Disconnect the negative battery terminal. Refer to pg-50, "removal and

installation (battery)".

Remove cluster lid c lower. Refer to ip-20, "re ...