Nissan Sentra Service Manual: Basic inspection

Diagnosis and repair workflow

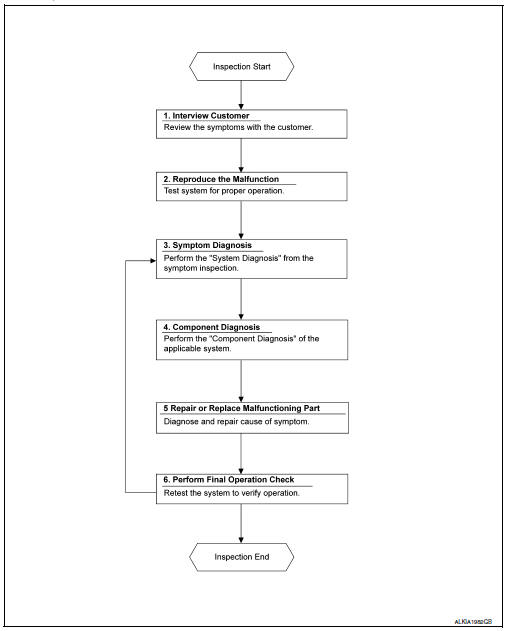

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1. OBTAIN INFORMATION ABOUT SYMPTOM

Interview the customer to obtain as much information as possible about the conditions and environment under which the malfunction occurred.

>> GO TO 2.

2. CONFIRM THE SYMPTOM

Check the malfunction on the vehicle that the customer describes.

Inspect the relation of the symptoms and the condition when the symptoms occur.

>> GO TO 3.

3. IDENTIFY THE MALFUNCTIONING SYSTEM WITH SYMPTOM DIAGNOSIS

Use Symptom diagnosis from the symptom inspection result in step 2 and then identify where to start performing the diagnosis based on possible causes and symptoms. Refer to WW-46, "Symptom Table".

>> GO TO 4.

4. PERFORM THE COMPONENT DIAGNOSIS OF THE OF THE APPLICABLE SYSTEM

Perform the diagnosis with Component diagnosis of the applicable system.

>> GO TO 5.

5. REPAIR OR REPLACE THE MALFUNCTIONING PARTS

Repair or replace the specified malfunctioning parts.

>> GO TO 6.

6. FINAL CHECK

Check that malfunctions are not reproduced when obtaining the malfunction information from the customer, referring to the symptom inspection result in step 2.

Are the malfunctions corrected? YES >> Inspection End.

NO >> GO TO 3.

Wiring diagram

Wiring diagram

Wiper and washer system

Wiring diagram - with intelligent key

Wiring diagram - without intelligent key

...

Other materials:

P050A, P050B, P050E Cold start control

Description

ECM controls ignition timing and engine idle speed when engine is started

with pre-warming up condition.

This control promotes the activation of three way catalyst by heating the

catalyst and reduces emissions.

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P050A, P050B or P050E ...

System

System Description

Operation description

A/C control transmits rear window defogger switch signal to A/C auto

amp. when rear window defogger

switch turns ON while ignition switch is ON.

A/C auto amp. transmits rear window defogger switch signal to BCM

Bcm transmits rear window defogg ...

Evap canister

Exploded View

EVAP canister bracket

EVAP canister filter drain hose

EVAP canister filter

EVAP canister protector

EVAP hose

EVAP canister vent control valve

O-ring

EVAP canister

O-ring

EVAP canister control pressure sensor

Clip

Nut

Removal and Installation

EVAP ...