Nissan Sentra Service Manual: Unit removal and installation

Front suspension member

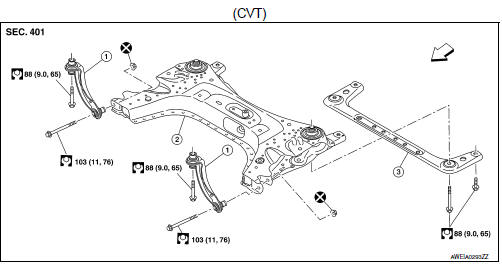

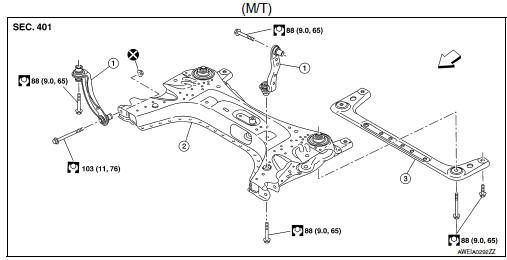

Exploded View

- Upper link

- Front suspension member

- Member stay

Front

Front

- Upper link

- Front suspension member

- Member stay

Front

Front

Removal and Installation

REMOVAL

- Remove the front wheel and tire using power tool. Refer to WT-47, "Exploded View".

- Remove the front under cover and the engine under cover. Refer to EXT-30, "FRONT UNDER COVER : Removal and Installation".

- Disconnect the steering gear from the lower shaft. Refer to ST-12, "Removal and Installation".

- Disconnect the steering outer socket from the steering knuckle. Refer to ST-14, "Removal and Installation".

- Remove the nut and bolt from the lower ball joint. Disconnect the transverse link from the steering knuckle. Refer to FAX-8, "Exploded View".

- Remove the rear torque rod and the rear torque rod bracket.

- MRA8DE (M/T): Refer to EM-82, "M/T : Removal and Installation".

- MRA8DE (CVT): Refer to EM-86, "CVT : Removal and Installation".

- Disconnect the oxygen sensor. Refer to EX-5, "Removal and Installation".

- Disconnect the stabilizer connecting rod from the stabilizer bar. Refer to FSU-12, "Exploded View".

- Set a suitable jack under front suspension member.

CAUTION:

- At this step, the suitable jack must be set only for supporting the removal procedure. For details on jacking up the vehicle, refer to GI-31, "Garage Jack and Safety Stand and 2-Pole Lift".

- Do not damage the front suspension member with the suitable jack.

- Remove the lower bolts from the upper links.

- Remove the bolts and the member stay.

- Remove the front suspension member bolts.

- Gradually lower the suitable jack to remove the front suspension member from the vehicle.

CAUTION:

Make sure the front suspension member is stable when using the suitable jack.

- If replacing the front suspension member, perform the following procedures:

- Remove the steering gear. Refer to ST-14, "Exploded View".

- Remove the transverse links. Refer to FSU-10, "Exploded View".

- Remove the stabilizer bar, the stabilizer clamps, and the stabilizer bushings. Refer to FSU-12, "Exploded View".

- Remove the oxygen sensor bracket. Refer to EX-5, "Exploded View".

- Inspect the components. Refer to FSU-18, "Inspection".

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Do not reuse the transverse link nuts.

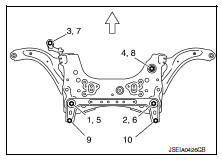

- Install the member stay bolts, the upper link bolts, and the front suspension member bolts in the order of 1 to 10 as shown (if equipped with the 6M/T).

Temporary tightening : 1 → 2→ 3 → 4

Final tightening (Specified torque) : 5 → 6 → 7 → 8 → 9 → 10

: Front

: Front

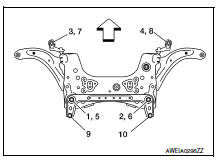

- Install the member stay bolts, the upper link bolts, and the front suspension member bolts in the order of 1 to 10 as shown (if equipped with the CVT).

Temporary tightening : 1 → 2→ 3 → 4

Final tightening (Specified torque) : 5 → 6 → 7 → 8 → 9 → 10

: Front

: Front

- Perform the final tightening of the nuts and bolts under unladen conditions with the tires on level ground.

- Complete the inspection. Refer to FSU-18, "Inspection".

Inspection

INSPECTION AFTER REMOVAL

Check the front suspension member for cracks, wear or damage. Replace components if necessary.

INSPECTION AFTER INSTALLATION

- Check the wheel sensor harness to be sure the connectors are fully seated.

- Check the neutral position of the steering angle sensor. Refer to BRC-54, "Work Procedure".

- Check the wheel alignment. Refer to FSU-6, "Inspection".

Steering knuckle

Steering knuckle

Exploded View

Steering knuckle

Splash guard

Wheel stud

Wheel hub and bearing

Disc brake rotor

Wheel hub lock nut

Nut retainer

Cotter pin

Removal and Installation

REMOVAL

...

Unit disassembly and assembly

Unit disassembly and assembly

Front coil spring and strut

Exploded View

Piston rod lock nut

Strut mount insulator

Strut mount bearing

Bound bumper

Coil spring

Lower rubber seat

Strut

Steering knuckle

Fro ...

Other materials:

Description

Number

Item

Description

1

Power supply

This means the power supply of fusible link or fuse.

2

Fusible link

“X” means the fusible link.

3

Number of fusible link/

fuse

This means the numbe ...

Child safety rear door lock

Child safety locks help prevent the rear doors

from being opened accidentally, especially when

small children are in the vehicle.

The child safety lock levers are located on the

edge of the rear doors.

When the lever is in the unlock position 2 , the

door can be opened from the outside ...

Removal and installation

Ecm

Exploded View

ECM bracket

ECM

Engine mounting insulator bracket

Removal and Installation

CAUTION:

Perform ADDITIONAL SERVICE WHEN REPLACING ECM. Refer to EC-135, "Work

Procedure".

REMOVAL

Remove battery. Refer to PG-50, "Removal and Installation (Battery)& ...