Nissan Sentra Owners Manual: Tire labeling

Federal law requires tire manufacturers to place standardized information on the sidewall of all tires. This information identifies and describes the fundamental characteristics of the tire and also provides the tire identification number (TIN) for safety standard certification. The TIN can be used to identify the tire in case of a recall.

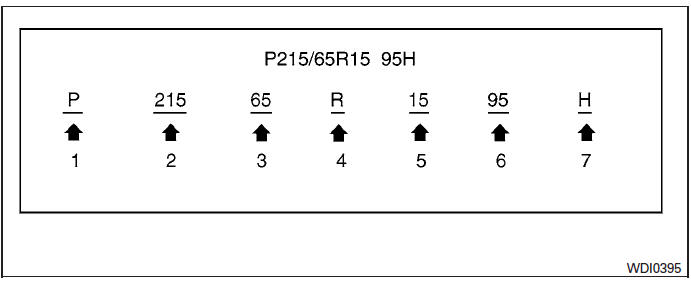

Tire size (example: P215/65R15

Tire size (example: P215/65R15

95H)

- P: The ŌĆ£PŌĆØ indicates the tire is designed for passenger vehicles (not all tires have this information).

- Three-digit number (215): This number gives the width in millimeters of the tire from sidewall edge to sidewall edge.

- Two-digit number (65): This number, known as the aspect ratio, gives the tireŌĆÖs ratio of height to width.

- R: The ŌĆ£RŌĆØ stands for radial.

- Two-digit number (15): This number is the wheel or rim diameter in inches.

- Two- or three-digit number (95): This number is the tireŌĆÖs load index. It is a measurement of how much weight each tire can support. You may not find this information on all tires because it is not required by law.

- H: Tire speed rating. You should not drive the vehicle faster than the tire speed rating.

Example

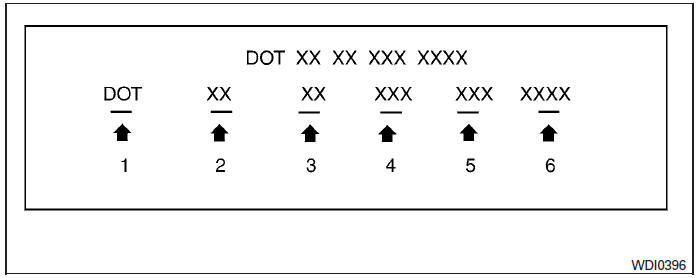

TIN (Tire Identification

TIN (Tire Identification

Number) for a

new tire (example: DOT XX XX XXX

XXXX)

- DOT: Abbreviation for the ŌĆ£Department Of TransportationŌĆØ. The symbol can be placed above, below or to the left or right of the Tire Identification Number.

- Two-digit code: ManufacturerŌĆÖs identification mark.

- Two-digit code: Tire size

- Three-digit code: Tire type code (Optional).

- Three-digit code: Date of Manufacture.

- Four numbers represent the week and year the tire was built. For example, the numbers 3103 means the 31st week of 2003. If these numbers are missing then look on the other sidewall of the tire.

Tire ply composition and

Tire ply composition and

material

The number of layers or plies of rubbercoated fabric in the tire. Tire manufacturers also must indicate the materials in the tire, which include steel, nylon, polyester and others.

Maximum permissible inflation

Maximum permissible inflation

pressure

This number is the greatest amount of air pressure that should be put in the tire. Do not exceed the maximum permissible inflation pressure.

Maximum load rating

Maximum load rating

This number indicates the maximum load in kilograms and pounds that can be carried by the tire. When replacing the tires on the vehicle, always use a tire that has the same load rating as the factory installed tire.

Term of ŌĆ£tubelessŌĆØ or ŌĆ£tube

Term of ŌĆ£tubelessŌĆØ or ŌĆ£tube

typeŌĆØ

Indicates whether the tire requires an inner tube (ŌĆ£tube typeŌĆØ) or not (ŌĆ£tubelessŌĆØ).

The word ŌĆ£radialŌĆØ

The word ŌĆ£radialŌĆØ

The word ŌĆ£radialŌĆØ is shown if the tire has radial structure.

Manufacturer or brand name

Manufacturer or brand name

Manufacturer or brand name is shown.

Other Tire-related Terminology

In addition to the many terms that are defined throughout this section, Intended Outboard Sidewall is (1) the sidewall that contains a whitewall, bears white lettering or bears manufacturer, brand, and/or model name molding that is higher or deeper than the same molding on the other sidewall of the tire, or (2) the outward facing sidewall of an asymmetrical tire that has a particular side that must always face outward when mounted on a vehicle.

Tire pressure

Tire pressure

Tire Pressure Monitoring System

(TPMS)

This vehicle is equipped with the Tire

Pressure Monitoring System (TPMS). It

monitors tire pressure of all tires except

the spare. When the low tire pressur ...

Types of tires

Types of tires

WARNING

When changing or replacing tires, be

sure all four tires are of the same type

(i.e., Summer, All Season or Snow) and

construction. A NISSAN dealer may be

able to hel ...

Other materials:

Text messaging

WARNING

Laws in some jurisdictions may restrict

the use of some of the applications and

features, such as social networking and

texting. Check local regulations for any

requirements.

Laws in some jurisdictions may restrict

the use of ŌĆ£Text-to-SpeechŌĆØ. Check loc ...

Readiness for inspection/maintenance (I/M) test

Due to legal requirements in some states and

Canadian Provinces, your vehicle may be required

to be in what is called the ŌĆ£ready conditionŌĆØ

for an Inspection/Maintenance (I/M) test of

the emission control system.

The vehicle is set to the ŌĆ£ready conditionŌĆØ when it

is driven through c ...

Diagnosis system (BCM) (without intelligent key system)

Common item

Common item : consult function (bcm - common item)

APPLICATION ITEM

CONSULT performs the following functions via CAN communication with BCM.

Direct Diagnostic Mode

Description

ECU identification

The BCM part number is displayed.

Self Diagnostic Result

...