Nissan Sentra Service Manual: Steering gear and linkage

Inspection

INSPECTION AFTER DISASSEMBLY

BOOT

-

Check boot for cracks. Replace if any damage is found.

STEERING GEAR ASSEMBLY HOUSING

-

Check steering gear assembly housing for damage and scratches. Replace if there are any abnormal conditions.

OUTER SOCKET AND INNER SOCKET

Ball joint swinging torque

-

Hook a spring balance to the ball stud and inner socket measuring point (*) and pull the spring balance. Make sure that the spring balance reads the specified value when ball stud and inner socket start to move. Replace outer socket and inner socket if they are outside the specification.

Tool number : — (J-44372)

Swinging torque : Refer to ST-19, "Power Steering Gear".

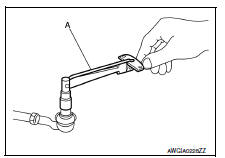

Ball joint rotating torque

-

Make sure that the reading is within the following specified range using Tool. Replace outer socket if the reading is outside the specification.

Tool number (A) : ST3127S000 (J-25765-A)

Rotating torque : Refer to ST-19, "Power Steering Gear".

INSPECTION AFTER INSTALLATION

-

Check if steering wheel turns smoothly when it is turned several times fully to the end of the left and right.

-

Check the steering wheel play, neutral position steering wheel, steering wheel turning force, and front wheel turning angle.

-

Steering wheel play: Refer to ST-5, "Inspection".

-

Neutral position steering wheel, steering wheel turning force, and front wheel turning angle: Refer to ST-5, "Inspection".

Steering column

Steering column

Inspection

STEERING COLUMN ASSEMBLY

Check each part of steering column assembly for damage or

other malfunctions. Replace entire steering column

assembly if any parts are damaged.

Me ...

Symptom diagnosis

Symptom diagnosis

Noise, vibration and harshness (NVH) troubleshooting

NVH Troubleshooting Chart

Use the chart below to find the cause of the symptom. If

necessary, repair or replace these parts.

×: Appl ...

Other materials:

The illumination control switch is inoperative

Description

If any of the following malfunctions is found for the illumination control

switch operation.

All switches are inopera

The specified switch cannot be operated

Diagnosis procedure

1.Check illumination control switch signal circuit

Check the illumination control switch signal ...

iPod®* player operation without Navigation System (if so equipped)

Connecting iPod®

WARNINGDo not connect, disconnect or operate the

USB device while driving. Doing so can be

a distraction. If distracted you could lose

control of your vehicle and cause an accident

or serious injury.

CAUTION

Do not force the USB device into the

U ...

Low tire pressure warning lamp does not turn on

Low Tire pessure Warning Lamp Does Not Come On When Ignition Switch Is

Turned On

Note:

The Signal Tech II Tool (J-50190) can be used to perform the following

functions. Refer to the Signal Tech II

User Guide for additional information.

Activate and display TPMS transmitter IDs

Display t ...