Nissan Sentra Service Manual: Removal and installation

Generator

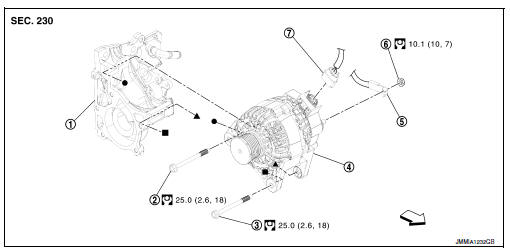

Exploded view

- Thermostat housing

- Generator bolt (upper)

- Generator bolt (lower)

- Generator

- B” terminal harness

- “B” terminal nut

- Generator harness connector

Front

Front

Removal and installation

Note:

When removing components such as hoses,tubes\lines,etc,cap or plug openings to prevent fluid from spilling.

Removal

- Disconnect the battery negative terminal. Refer to PG-50, "Removal and Installation (Battery)".

- Remove cooling fan. Refer to CO-17, "Removal and Installation".

- Remove drive belt. Refer to em-15, "removal and installation".

- Disconnect generator harness connector.

- Remove “B” terminal nut, and then disconnect “B” terminal harness.

- Remove generator bolt (upper).

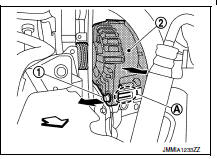

- Completely loosen generator bolt (lower) (1), and pull it out until the bolt head is in contact with the side member. And then, remove the generator (2) by pulling it forward.

: Front

: Front

Note:

The generator can be removed together with the bolts by pulling it forward and using the thermostat housing bolt hole cutout (a).

- Remove generator upward from the vehicle.

Installation

- Installation is in the reverse order of removal.

- Refill engine coolant. Refer to co-12, "changing engine coolant".

Caution:

- Temporarily tighten the generator bolts in order from the lower to the upper, and then tighten them in order from the upper to the lower.

- For the generator, the front side (pulley side) surface is the reference surface. Fit the reference surface to the generator mounting part, and then tighten the bolts.

- Be careful to tighten “b” terminal nut carefully.

- For this model, the power generation voltage variable control system that controls the power generation voltage of the generator has been adopted. Therefore, the power generation voltage variable control system operation inspection should be performed after replacing the generator, and then make sure that the system operates normally. Refer to chg-8, "system description".

Inspection

Generator pulley inspection

Perform the following.

- Make sure that generator pulley does not rattle.

- Make sure that generator pulley nut is tight.

Note:

Replace generator as an assembly if necessary.

Symptom diagnosis

Symptom diagnosis

Charging system

Symptom table

...

Service data and specifications (SDS)

Service data and specifications (SDS)

Generator

*: Always check with the parts department for the latest parts information. ...

Other materials:

Brake fluid

Inspection

BRAKE FLUID LEVEL

Make sure that the brake fluid level in the reservoir tank is between

the MAX and MIN lines.

Visually check around the reservoir tank for brake fluid leakage.

If the brake fluid level is excessively low, check the brake system

for leakage.

If brake warning ...

Performance test

Inspection

INSPECTION PROCEDURE

Connect recovery/recycling/recharging equipment (for HFC-134a) or

manifold gauge.

Start the engine, and set to the following condition.

Test condition

Maintain test condition until A/C system becomes stable. (Approximately

10 minutes)

Check t ...

Rear power window motor

Removal and Installation

REMOVAL

Remove the rear door glass regulator (1). Refer to GW-21,

"Removal and Installation"

Remove the screws and the rear power window motor (2).

INSTALLATION

Installation is in the reverse order of removal. ...