Nissan Sentra Service Manual: Rear shock absorber

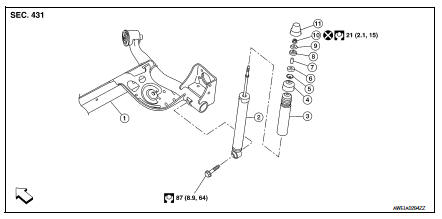

Exploded View

- Rear suspension beam

- Shock absorber

- Bound bumper

- Bound bumper cover

- Washer

- Bushing

- Distance tube

- Bushing

- Washer

- Piston rod lock nut

- Cap

Front

Front

Removal and Installation

REMOVAL

- Remove the rear shock tower access flap.

- Remove the cap from the rear shock absorber.

- Remove the piston rod lock nut (1).

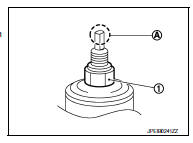

NOTE:

To loosen the piston rod lock nut, hold the tip (A) of the piston rod.

- Remove the washer and the bushing.

- Set a suitable jack under the rear suspension beam.

CAUTION:

- At this step, the jack must be set only for supporting the removal procedure. For details on jacking up the vehicle, refer to GI-31, "Garage Jack and Safety Stand and 2-Pole Lift".

- Do not damage the rear suspension beam with the jack.

- Make sure the rear suspension beam is stable when using the jack.

- Remove the lower shock absorber bolt.

- Remove the rear shock absorber.

- Remove the bushing, the distance tube, the washer, the bound bumper cover, and the bound bumper from the shock absorber.

- Inspect the components. Refer to RSU-10, "Inspection".

INSTALLATION

Installation is in the reverse order of removal.

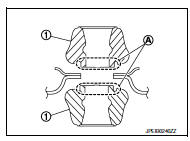

- To install the bushings (1), securely insert the protrusion (A) into the hole in the vehicle body.

- Install the washer (1) in the direction shown.

: Bushing side

: Bushing side

- Perform the final tightening of the bolts and nuts under unladen conditions with the tires on level ground.

- Hold the tip (A) of the piston rod. Tighten the piston rod lock nut (1) to the specification.

CAUTION:

Do not reuse the piston rod lock nut.

- When installing the cap, securely engage the cap groove (A) with the flange on the vehicle body.

- After replacing the shock absorber, always follow the disposal procedure

to discard the old shock absorber.

Refer to RSU-10, "Disposal".

Inspection

INSPECTION AFTER REMOVAL

Shock Absorber

Check the following items and replace the parts if necessary.

- Check the shock absorber for oil leaks, deformation, cracks, and other damage.

- Check the piston rod for damage, uneven wear, and distortion.

Bound Bumper, Bushing

Check for cracks and damage. Replace the parts if necessary.

Washer, Bound Bumper Cover, Distance Tube

- Check for cracks and damage. Replace the parts if necessary.

Disposal

- Set the shock absorber horizontally with the piston rod fully extended.

- Drill a 2 – 3 mm (0.08 – 0.12 in) hole at the position (

) from the top as shown to release gas gradually.

CAUTION:

- Wear eye protection (safety glasses).

- Wear gloves.

- Be careful with metal chips or oil blown out by the compressed gas.

NOTE:

- Drill vertically in this direction (

). - Drill directly to the outer tube avoiding brackets.

- The gas is clear, colorless, odorless, and harmless.

(A) : 20 – 30 mm (0.79 – 1.18 in)

- Position the drilled hole downward and drain oil by moving the piston rod several times.

CAUTION:

Dispose of drained oil according to the law and local regulations.

Coil spring

Coil spring

Exploded View

Upper rubber seat

Coil spring

Lower rubber seat

Rear suspension beam

Front

Removal and Installation

REMOVAL

Set a suitable jack under the rear suspension beam.

...

Other materials:

C1120, C1122, C1124, C1126 ABS In valve system

DTC Logic

Dtc detection logic

DTC

Display Item

Malfunction detected condition

Possible causes

C1120

FR LH IN ABS SOL

When a malfunction is detected in front LH ABS IN

valve.

Harness or connector

ABS actuator and electric unit

(control unit)

...

Starting the engine

Apply the parking brake.

CVT model:

Move the shift lever to P (Park) or N (Neutral).

P (Park) is recommended.

The shift lever cannot be moved out of

P (Park) and into any of the other gear

positions if the ignition switch is

turned to the OFF position or if the key

is removed from th ...

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT

BELT PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver and front passenger for certain

types of collision. Information necessary to service the system ...