Nissan Sentra Service Manual: Radiator

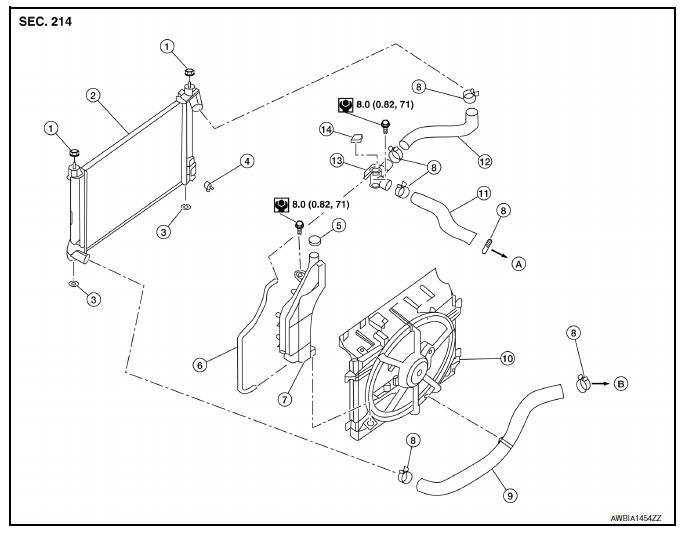

Exploded View

- Mounting rubber (upper)

- Radiator

- Mounting rubber (lower)

- Radiator drain plug

- Reservoir tank cap

- Reservoir tank hose

- Reservoir tank

- Clamp

- Radiator hose (lower)

- Fan shroud and motor assembly

- Radiator hose (upper)

- Filler neck hose

- Filler neck

- Radiator filler cap

- To water outlet

- To water inlet

WARNING:

Do not remove the radiator cap when the engine is hot. Serious burns could occur from high-pressure engine coolant escaping from the radiator. Wrap a thick cloth around the cap. Slowly push down and turn it a quarter turn to allow built-up pressure to escape. Carefully remove the cap by pushing it down and turning it all the way.

NOTE:

When removing components such as hoses, tubes/lines, etc., cap or plug openings to prevent fluid from spilling.

Removal and Installation

REMOVAL

- Disconnect the negative battery terminal. Refer to PG-52, "Removal and Installation".

- Remove fan shroud and motor assembly. Refer to CO-17, "Removal and Installation".

- Remove radiator cap, open radiator drain plug and drain engine coolant from radiator. Refer to CO-12, "Changing Engine Coolant".

CAUTION:

- Perform this step when the engine is cold.

- Do not spill engine coolant on the drive belt.

- Remove radiator hose (lower). Refer to CO-15, "Exploded View".

- Remove condenser bolts from radiator.

- Remove the radiator from the vehicle.

CAUTION:

Be careful not to damage radiator core and condenser assembly core.

INSTALLATION

Installation is in the reverse order of removal.

- After installation, refill engine coolant and check for leaks. Refer to CO-12, "Changing Engine Coolant" and CO-11, "System Inspection".

NOTE:

When installing radiator core support (upper), check that both upper and lower mounts of radiator and air conditioner condenser are inserted in the mounting holes of radiator core support (upper, lower).

CAUTION:

Do not spill engine coolant in engine compartment. Use a shop cloth to absorb engine coolant.

Inspection

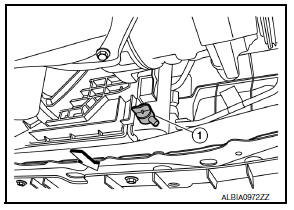

INSPECTION AFTER INSTALLATION

- Check that the reservoir tank cap is tightened.

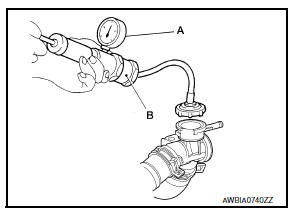

- Check for leaks of engine coolant using Tool (B) and suitable tool

(A). Refer to CO-11, "System Inspection".

Tool number : EG17650301 (J-33984-A)

Testing pressure : Refer to CO-28, "Radiator".

WARNING:

Do not remove the radiator cap when the engine is hot. Serious burns could occur from high pressure engine coolant escaping from the radiator.

CAUTION:

Higher pressure than specified may cause radiator damage.

- Start and warm up the engine. Visually check that there are no engine coolant or CVT fluid leaks.

Cooling fan

Cooling fan

Component

Fan shroud and motor assembly

WARNING:

Do not remove the radiator cap when the engine is hot. Serious burns

could occur from high-pressure

engine coolant escaping from the ra ...

Other materials:

Diagnosis system (bcm) (with intelligent key system)

Common item

Common item : consult function (bcm - common item)

Application item

Consult performs the following functions via can communication with bcm.

Direct diagnostic mode

Description

ECU identification

The BCM part number is displayed.

Self diagnostic result

...

P0965 Pressure control solenoid B

DTC Logic

DTC DETECTION LOGIC

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

Possible causes

P0965

PC SOLENOID B

(Pressure control solenoid B

control circuit range performance)

The detection conditions continuously for 5

seco ...

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver and front passenger for certain

types of collision. Information necessary to service the system ...