Nissan Sentra Service Manual: Power supply and ground circuit

Diagnosis Procedure

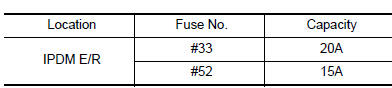

1.CHECK FUSE

Check that the following fuse is not fusing.

Is the fuse fusing? YES >> Replace the fuse after repairing the applicable circuit.

NO >> GO TO 2.

2.CHECK GROUND CONNECTION

- Turn ignition switch OFF

- Check ground connection E9 and E15. Refer to GI-42, "Circuit Inspection".

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace ground connection.

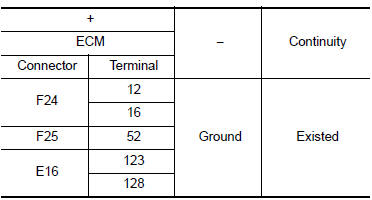

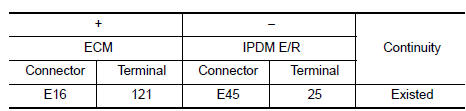

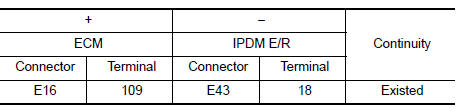

3.CHECK ECM GROUND CIRCUIT

- Disconnect ECM harness connectors.

- Check the continuity between ECM harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

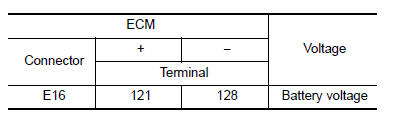

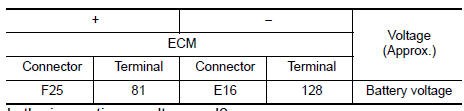

4.CHECK ECM POWER SUPPLY (MAIN)-1

- Reconnect ECM harness connector.

- Turn ignition switch ON.

- Check the voltage between ECM harness connector terminals.

Is the inspection result normal? YES >> GO TO 5.

NO >> GO TO 6.

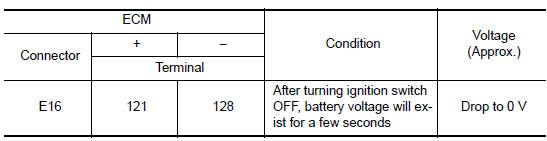

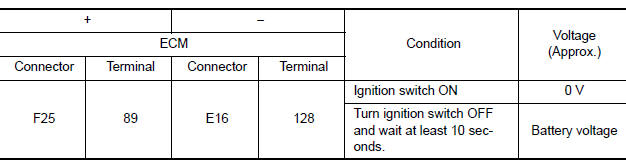

5.CHECK ECM POWER SUPPLY (MAIN)-2

- Turn ignition switch OFF and wait at least 10 seconds.

- Check the voltage between ECM harness connector terminals as per the following.

Is the inspection result normal? YES >> GO TO 9.

NO >> GO TO 7.

6.CHECK ECM POWER SUPPLY (MAIN) CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connectors.

- Disconnect IPDM E/R harness connector.

- Check the continuity between ECM harness connector and IPDM E/R harness connector.

- Also check harness for short to ground.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

7.CHECK ECM RELAY CONTROL SIGNAL

Check the voltage between ECM harness connector terminals as per the following.

Is the inspection result normal? YES >> Check Intermittent incident. Refer to GI-39, "Intermittent Incident".

NO >> GO TO 8.

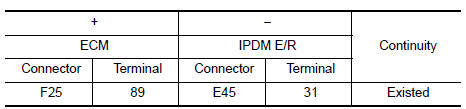

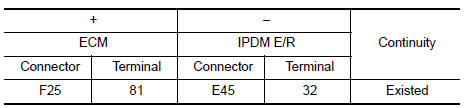

8.CHECK ECM RELAY CONTROL SIGNAL CIRCUIT

- Turn ignition switch OFF

- Disconnect ECM harness connector.

- Disconnect IPDM E/R harness connector

- Check the continuity between ECM harness connector and IPDM E/R harness connector.

- Also check harness for short to ground and to power.

Is the inspection result normal? YES >> Replace IPDM E/R. Refer to PCS-58, "Removal and Installation" (with intelligent key), PCS-58, "Removal and Installation" (without intelligent key).

NO >> Repair or replace error-detected parts.

9.CHECK IGNITION SWITCH SIGNAL

- Turn ignition switch ON.

- Check the voltage between ECM harness connector terminals.

Is the inspection result normal? YES >> GO TO 11.

NO >> GO TO 10.

10.CHECK IGNITION SWITCH SIGNAL CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Disconnect IPDM E/R harness connector.

- Check the continuity between ECM harness connector and IPDM E/R harness connector.

- Also check harness for short to ground and to power.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

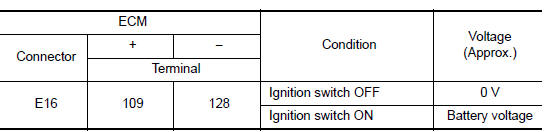

11.CHECK ECM POWER SUPPLY (BACK-UP)

Check the voltage between ECM harness connector terminals.

Is the inspection result normal? YES >> Check Intermittent Incident. Refer to GI-39, "Intermittent Incident".

NO >> GO TO 12.

12.CHECK ECM POWER SUPPLY (BACK-UP) CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Disconnect IPDM E/R harness connector.

- Check the continuity between ECM harness connector and IPDM E/R harness connector.

- Also check harness for short to ground.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

Trouble diagnosis - specification

value

Trouble diagnosis - specification

value

Description

The specification (SP) value indicates the tolerance of the value that is

displayed in “SPEC” of “DATA MONITOR”

mode of CONSULT during normal operation of the Engin ...

U0101 can comm circuit

U0101 can comm circuit

Description

CAN (Controller Area Network) is a serial communication line for real time

application. It is an on-vehicle multiplex

communication line with high data communication speed and excellen ...

Other materials:

Cooling fan

Component Function Check

1.CHECK COOLING FAN FUNCTION

With CONSULT

Turn ignition switch ON.

Perform “FAN” in “ACTIVE TEST” mode of “ENGINE” using CONSULT

Check that cooling fan operates at low speed or high speed.

Without CONSULT

Activate IPDM E/R auto ...

Periodic maintenance

M/T OIL

Inspection

OIL LEAKAGE

Make sure that gear oil is not leaking from transaxle or around it.

OIL LEVEL

Remove filler plug (1) and gasket from transaxle case.

Check the oil level from filler plug mounting hole as shown.

CAUTION:

Do not start engine while checking oil level.

Se ...

System

VDC/TCS/ABS

VDC/TCS/ABS : System Diagram

VDC/TCS/ABS : System Description

The system switches fluid pressure of each brake caliper and

each wheel cylinder to increase, to hold, or to

decrease according to signals from control unit in ABS actuator and electric

unit (control unit) ...