Nissan Sentra Service Manual: P099C Shift solenoid G

DTC Logic

| DTC | CONSULT screen terms (Trouble diagnosis content) | DTC detection condition | Possible causes |

| P099C | SHIFT SOLENOID G (Shift Solenoid G Control Circuit High) | The TCM high clutch & reverse brake solenoid

valve current monitor reading is 200 mA or

less continuously for 200 msec or more under

the following diagnosis conditions: Diagnosis conditions

|

|

DTC CONFIRMATION PROCEDURE

1.PREPARATION BEFORE WORK

If another –≤–В—ЪDTC CONFIRMATION PROCEDURE–≤–В—Ь occurs just before, turn ignition switch OFF and wait for at least 10 seconds, then perform the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

- Start the engine and wait for 5 seconds or more

- Check the first trip DTC.

Is –≤–В—ЪP099C–≤–В—Ь detected? YES >> Go to TM-216, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

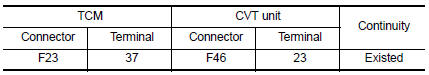

1.CHECK CIRCUIT BETWEEN TCM AND CVT UNIT

- Turn ignition switch OFF.

- Disconnect TCM connector and CVT unit connector.

- Check continuity between TCM harness connector terminal and CVT unit harness connector terminal.

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace malfunctioning parts.

2.CHECK HIGH CLUTCH & REVERSE BRAKE SOLENOID VALVE

Check high clutch & reverse brake solenoid valve. Refer to TM-216, "Component Inspection".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-39, "Intermittent Incident".

NO >> Repair or replace malfunctioning parts.

Component Inspection

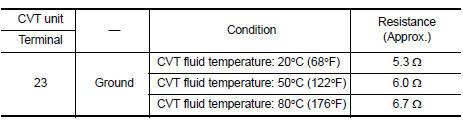

1.CHECK HIGH CLUTCH & REVERSE BRAKE SOLENOID VALVE

Check resistance between CVT unit connector terminal and ground.

Is the inspection result normal? YES >> INSPECTION END

NO >> There is a malfunction of high & reverse brake solenoid valve. Replace transaxle assembly. Refer to TM-283, "Removal and Installation".

P099B Shift solenoid G

P099B Shift solenoid G

DTC Logic

DTC DETECTION LOGIC

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

Possible causes

P099B

SHIFT SOLENOID G

(Shift Solenoid G ...

P1586 G Sensor

P1586 G Sensor

DTC Logic

DTC DETECTION LOGIC

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

Possible causes

P1586

G Sensor

(Gravity Sensor Circuit)

...

Other materials:

U1010 Control unit (CAN)

Description

Air bag diagnosis sensor performs self-tests on key ON. If CAN communication

failure within control unit is

detected, DTC is set.

DTC Logic

DTC DETECTION LOGIC

CONSULT name

DTC

DTC detecting condition

Repair order

CAN CONTROL UNIT FAILURE

U1010

CAN ...

Bluetooth¬Ѓ settings

To access and adjust the settings for the

Bluetooth¬Ѓ Hands-Free Phone System:

Press the SETTING button.

Use the TUNE/SCROLL knob to select

вАЬBluetoothвАЭ and then press the ENTER button:

Bluetooth

Select вАЬOnвАЭ or вАЬOffвАЭ to turn the vehicleвАЩs

Bluetooth¬Ѓ system on or ...

Power outlet

Center Console

Console Box (if so equipped)

The power outlets are for powering electrical

accessories such as cellular telephones. They

are rated at 12 volt, 120W (10A) maximum.

The power outlets are powered only when the

ignition switch is in the ACC or ON position.

CAUTION

The ...