Nissan Sentra Service Manual: P0963 Pressure control solenoid A

DTC Logic

DTC DETECTION LOGIC

| DTC | CONSULT screen terms (Trouble diagnosis content) | DTC detection condition | Possible causes |

| P0963 | PC SOLENOID A (Pressure Control Solenoid A Control Circuit High) | The line pressure solenoid valve current is 200

mA or less continuously for 200 msec or more

under the following diagnosis conditions: Diagnosis conditions

|

|

DTC CONFIRMATION PROCEDURE

1.PREPARATION BEFORE WORK

If another “DTC CONFIRMATION PROCEDURE” occurs just before, turn ignition switch OFF and wait for at least 10 seconds, then perform the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

- Start the engine and wait for 5 seconds or more.

- Check the first trip DTC.

Is “P0963” detected? YES >> Go to TM-203, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

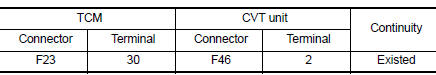

1.CHECK CIRCUIT BETWEEN TCM AND CVT UNIT

- Turn ignition switch OFF.

- Disconnect TCM connector and CVT unit connector.

- Check continuity between TCM harness connector terminal and CVT unit harness connector terminal.

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace malfunctioning parts.

2.CHECK LINE PRESSURE SOLENOID VALVE

Check line pressure solenoid valve. Refer to TM-203, "Component Inspection".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-39, "Intermittent Incident".

NO >> Repair or replace malfunctioning parts.

Component Inspection

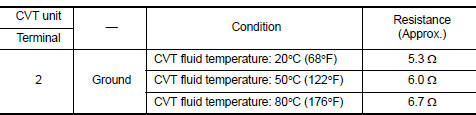

1.CHECK LINE PRESSURE SOLENOID VALVE

Check resistance between CVT unit connector terminal and ground.

Is the inspection

Is the inspection

result normal?

YES >> INSPECTION END

NO >> There is a malfunction of line pressure solenoid valve. Replace transaxle assembly. Refer to TM- 283, "Removal and Installation".

P0962 Pressure control solenoid A

P0962 Pressure control solenoid A

DTC Logic

DTC DETECTION LOGIC

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

Possible causes

P0962

PRESSURE CONTROL SOLENOID

A

(Pre ...

P0965 Pressure control solenoid B

P0965 Pressure control solenoid B

DTC Logic

DTC DETECTION LOGIC

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

Possible causes

P0965

PC SOLENOID B

(Pressure control sol ...

Other materials:

Front passenger side power window does not operate

When both power window main switch and front power window switch are

operated

WHEN BOTH POWER WINDOW MAIN SWITCH AND FRONT POWER WINDOW SWITCH ARE OPERATED

: Diagnosis Procedure

1.CHECK FRONT POWER WINDOW SWITCH (PASSENGER SIDE)

Check front power window switch (passenger side).

Refer to PW ...

B1430, B1432 Seat belt pre-tensioner LH

Description

DTC B1430, B1432 SEAT BELT PRE-TENSIONER LH

The seat belt pre-tensioner LH is wired to the air bag diagnosis sensor unit.

The air bag diagnosis sensor unit

will monitor for opens and shorts in detected lines to the seat belt pre-tensioner

LH.

PART LOCATION

Refer to SRC-5, " ...

Can communication circuit

Diagnosis procedure

1.Connector inspection

Turn the ignition switch OFF.

Disconnect the battery cable from the negative terminal.

Disconnect all the unit connectors on can communication system.

Check terminals and connectors for damage, bend and loose connection.

Is the inspection resu ...