Nissan Sentra Service Manual: P0137 HO2S2

DTC Logic

DTC DETECTION LOGIC

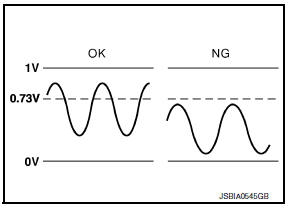

The heated oxygen sensor 2 has a much longer switching time between rich and lean than the air fuel ratio (A/F) sensor 1. The oxygen storage capacity of the three way catalyst (manifold) causes the longer switching time. To judge the malfunctions of heated oxygen sensor 2, ECM monitors whether the maximum voltage of the sensor is sufficiently high during the various driving condition such as fuelcut.

| DTC No. | CONSULT screen terms (Trouble diagnosis content) | DTC detecting condition | Possible cause |

| P0137 | HO2S2 (B1) (O2 sensor circuit low voltage bank 1 sensor 2) | The maximum voltage from the heated oxygen sensor 2 is not reached to the specified voltage. |

|

DTC CONFIRMATION PROCEDURE

1.INSPECTION START

Do you have CONSULT? Do you have CONSULT? YES >> GO TO 2.

NO >> GO TO 5.

2.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

For better results, perform “DTC WORK SUPPORT” at a temperature of 0 to 30°C (32 to 86°F).

>> GO TO 3.

3.PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

- Turn ignition switch ON and select “DATA MONITOR” mode of “ENGINE” using CONSULT.

- Start engine and warm it up to normal operating temperature

- Turn ignition switch OFF and wait at least 10 seconds.

- Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

- Let engine idle for 1 minute.

- Make sure that “COOLANT TEMP/S” indicates more than 70°C (158°F).

If not, warm up engine and go to next step when “COOLANT TEMP/S” indication reaches 70°C (158°F).

- Open engine hood.

- Select “HO2S2 (B1) P1147” of “HO2S2” in “DTC WORK SUPPORT” mode of “ENGINE” using CONSULT.

- Follow the instruction of CONSULT.

NOTE:

It will take at most 10 minutes until “COMPLETED” is displayed.

- Touch “SELF-DIAG RESULT”.

Which is displayed on CONSULT screen? OK >> INSPECTION END

NG >> Proceed to EC-222, "Diagnosis Procedure".

CAN NOT BE DIAGNOSED>>GO TO 4.

4.PERFORM DTC CONFIRMATION PROCEDURE AGAIN

- Turn ignition switch OFF and leave the vehicle in a cool place (soak the vehicle).

- Perform DTC CONFIRMATION PROCEDURE again.

>> GO TO 3.

5.PERFORM COMPONENT FUNCTION CHECK

Perform component function check. Refer to EC-221, "Component Function Check".

NOTE:

Use component function check to check the overall function of the heated oxygen sensor 2 circuit. During this check, a 1st trip DTC might not be confirmed.

Is the inspection result normal? YES >> INSPECTION END

NO >> Proceed to EC-222, "Diagnosis Procedure".

Component Function Check

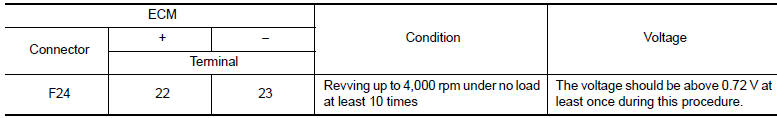

1.PERFORM COMPONENT FUNCTION CHECK-1

Without CONSULT

Without CONSULT

- Start engine and warm it up to normal operating temperature.

- Turn ignition switch OFF and wait at least 10 seconds.

- Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

- Let engine idle for 1 minute.

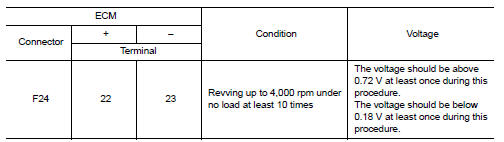

- Check the voltage between ECM harness connector and ground as per the following condition.

Is the inspection result normal? YES >> INSPECTION END

NO >> GO TO 2.

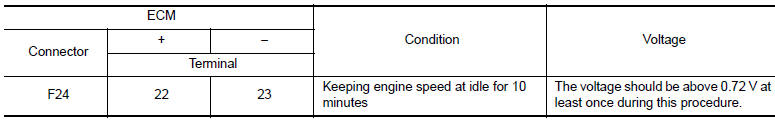

2.PERFORM COMPONENT FUNCTION CHECK-2

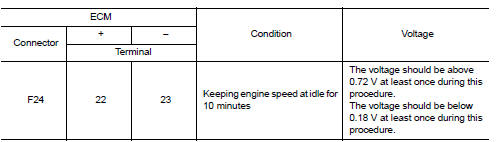

Check the voltage between ECM harness connector and ground as per the following condition.

Is the inspection result normal? YES >> INSPECTION END

NO >> GO TO 3.

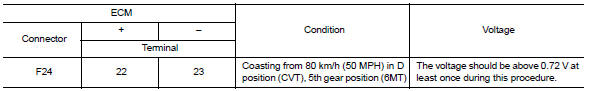

3.PERFORM COMPONENT FUNCTION CHECK-3

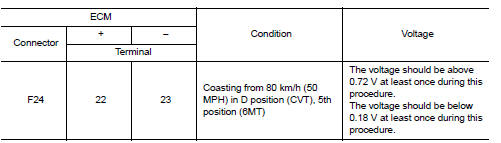

Check the voltage between ECM harness connector and ground as per the following condition.

Is the inspection result normal? YES >> INSPECTION END

NO >> Proceed to EC-222, "Diagnosis Procedure".

Diagnosis Procedure

1.CLEAR THE MIXTURE RATIO SELF-LEARNING VALUE

- Clear the mixture ratio self-learning value. Refer to EC-142, "Work Procedure".

- Run engine for at least 10 minutes at idle speed.

Is the 1st trip DTC P0171 detected? Is it difficult to start engine? YES >> Perform trouble diagnosis for DTC P0171. Refer to EC-246, "DTC Logic".

NO >> GO TO 2.

2.CHECK HO2S2 GROUND CIRCUIT

- Turn ignition switch OFF.

- Disconnect heated oxygen sensor 2 (HO2S2) harness connector.

- Disconnect ECM harness connector.

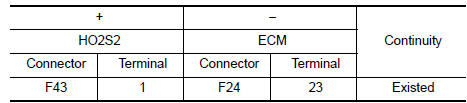

- Check the continuity between HO2S2 harness connector and ECM harness connector.

- Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace error-detected parts.

3.CHECK HO2S2 INPUT SIGNAL CIRCUIT

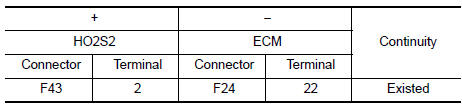

- Check the continuity between HO2S2 harness connector and ECM harness connector.

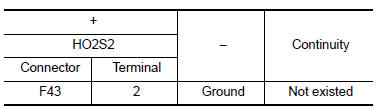

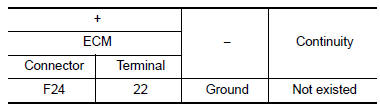

- Check the continuity between HO2S2 harness connector and ground, or ECM harness connector and ground.

- Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK HEATED OXYGEN SENSOR 2

Check the heated oxygen sensor 2. Refer to EC-223, "Component Inspection (HO2S2)".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-39, "Intermittent Incident".

NO >> Replace heated oxygen sensor 2. Refer to EX-5, "Exploded View".

Component Inspection (HO2S2)

1.INSPECTION START

Do you have CONSULT? Do you have CONSULT? YES >> GO TO 2.

NO >> GO TO 3.

2.CHECK HEATED OXYGEN SENSOR 2

With CONSULT

With CONSULT

- Turn ignition switch ON and select “DATA MONITOR” mode of “ENGINE” using CONSULT.

- Start engine and warm it up to normal operating temperature.

- Turn ignition switch OFF and wait at least 10 seconds.

- Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

- Let engine idle for 1 minute.

- Select “FUEL INJECTION” in “ACTIVE TEST” mode of “ENGINE” using CONSULT, and select “HO2S2 (B1)” as the monitor item with CONSULT.

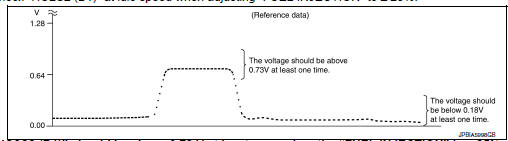

- Check “HO2S2 (B1)” at idle speed when adjusting “FUEL INJECTION” to ± 25%.

“HO2S2 (B1)” should be above 0.72 V at least once when the “FUEL INJECTION” is + 25%.

“HO2S2 (B1)” should be below 0.18 V at least once when the “FUEL INJECTION” is − 25%.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace heated oxygen sensor 2. Refer to EX-5, "Exploded View".

3.CHECK HEATED OXYGEN SENSOR 2-1

Without CONSULT

Without CONSULT

- Start engine and warm it up to normal operating temperature.

- Turn ignition switch OFF and wait at least 10 seconds.

- Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load

- Let engine idle for 1 minute

- Check the voltage between ECM harness connector and ground as per the following condition.

Is the inspection result normal? YES >> INSPECTION END

NO >> GO TO 4.

4.CHECK HEATED OXYGEN SENSOR 2-2

Check the voltage between ECM harness connector and ground as per the following condition.

Is the inspection result normal? YES >> INSPECTION END

NO >> GO TO 5.

5.CHECK HEATED OXYGEN SENSOR 2-3

Check the voltage between ECM harness connector and ground as per the following condition.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace heated oxygen sensor 2. Refer to EX-5, "Exploded View".

P0132 A/F SENSOR 1

P0132 A/F SENSOR 1

DTC Logic

DTC DETECTION LOGIC

To judge the malfunction, the diagnosis checks that the A/F signal computed

by ECM from the A/F sensor 1

signal is not inordinately high.

DTC No.

CONSULT ...

P0138 HO2S2

P0138 HO2S2

DTC Logic

DTC DETECTION LOGIC

The heated oxygen sensor 2 has a much longer switching time between rich and

lean than the air fuel ratio (A/

F) sensor 1. The oxygen storage capacity of the three w ...

Other materials:

Condenser

Exploded view

Core support upper cover

High-pressure pipe

High-pressure flexible hose

Refrigerant pressure sensor

Condenser and liquid tank assembly

Core support upper

Front

Condenser

Condenser : removal and installation

REMOVAL

Discharge the refrigerant. Refer to HA-23, & ...

Unit disassembly and assembly

Steering gear and linkage

Exploded View

Outer socket

Boot clamp (small diameter)

Boot

Boot clamp (large diameter)

Inner socket

Gear housing assembly

Disassembly and Assembly

DISASSEMBLY

Loosen outer socket lock nut, and remove outer socket.

CAUT ...

Basic inspection

Diagnosis and repair work flow

Work flow

Overall sequence

Detailed flow

1.Get information for symptom

Get detailed information from the customer about the symptom (the

condition and the environment when

the incident/malfunction occurs).

Check operation condition of the component o ...