Nissan Sentra Service Manual: Oil filter

Removal and Installation

REMOVAL

- Remove engine under cover. Refer to EXT-16, "Exploded View".

- Drain engine oil. Refer to LU-8, "Draining".

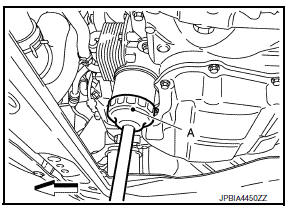

- Remove the oil filter using Tool (A) as shown.

: Front

Tool number : KV10115801 (J-38956)

WARNING:

Be careful not to burn yourself, as the engine oil may be hot.

CAUTION:

- When removing, prepare a shop cloth to absorb any oil leaks or spills.

- Do not allow engine oil to adhere to the drive belts.

- Completely wipe off any oil that adheres to the engine and the vehicle.

- The oil filter is provided with a relief valve. Use a Genuine NISSAN oil filter or equivalent.

INSTALLATION

- Remove foreign materials adhering to the oil filter installation surface.

- Apply new engine oil to the oil seal contact surface of new oil filter.

- Screw oil filter manually until it touches the installation surface, then tighten it by 2/3 turn (A), or tighten to specification.

Oil filter : 18.0 NВ·m (1.8 kg-m, 13 ft-lb)

Tool number : KV10115801 (J-38956)

- Refill engine with new engine oil. Refer to LU-9, "Refilling".

- Install engine under cover. Refer to EXT-16, "Exploded View".

Inspection

INSPECTION AFTER INSTALLATION

- Check the engine oil level. Refer to LU-7, "Inspection".

- Start the engine, and check that there are no leaks of engine oil.

- Stop the engine and wait for 10 minutes.

- Check the engine oil level, and adjust the level. Refer to LU-7, "Inspection".

Engine oil

Engine oil

Inspection

Engine oil level

Note:

Before starting engine, put vehicle horizontally and check the engine oil

level. If engine is already started, stop

it and allow 10 minutes before checking.

...

Removal and installation

Removal and installation

OIL COOLER

Exploded View

M/T models

Clamp

Water hose

Clamp

Water hose

Oil cooler

O-rings

CVT models

Clamp

Water hose

Clamp

Water hose

Water hose clip

Oil coole ...

Other materials:

Starter motor drive control

STARTER MOTOR DRIVE CONTROL : System Description

SYSTEN DIAGRAM

*1: CVT models

*2: M/T models

INPUT/OUTPUT SIGNAL CHART

Sensor

Input signal to ECM

ECM function

Actuator

Crankshaft position sensor (POS)

Engine speed

Piston position

Starter ...

Abs branch line circuit

Diagnosis procedure

1.CHECK CONNECTOR

Turn the ignition switch OFF.

Disconnect the battery cable from the negative terminal.

Check the terminals and connectors of the ABS actuator and electric unit

(control unit) for damage, bend

and loose connection (unit side and connector side).

...

C1140 Actuator relay system

DTC Logic

DTC DETECTION LOGIC

DTC

Display Item

Malfunction detected condition

Possible causes

C1140

ACTUATOR RLY

When a malfunction is detected in actuator relay.

Harness or connector

ABS actuator and electric unit

(control unit)

Fusible link ...