Nissan Sentra Service Manual: G Sensor

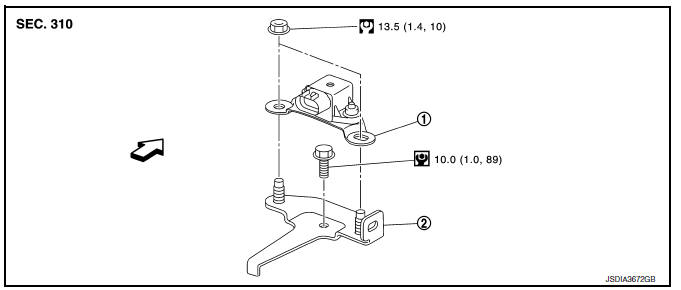

Exploded View

- G sensor

- Bracket

Vehicle front

Vehicle front

NВ·m (kg-m, ft-lb)

NВ·m (kg-m, ft-lb)

NВ·m (kg-m, in-lb)

NВ·m (kg-m, in-lb)

Removal and Installation

WARNING:

Do not leave any objects (screwdrivers, tools, etc.) on the seat during seat repair. It can lead to personal injury if the side air bag module should accidentally deploy.

CAUTION:

- Do not drop or strike G sensor, because it has little tolerance for impact.

- Do not use a power tool and avoid impact.

REMOVAL

- Disconnect the negative and positive battery terminals and wait at least three minutes. Refer to PG-50, "Removal and Installation (Battery)".

- Remove driver seat. Refer to SE-18, "DRIVER SIDE : Removal and Installation - Seat Assembly".

- Remove center pillar lower garnish (left side) and dash side finisher (left side). Refer to INT-27, "CENTER PILLAR LOWER FINISHER : Removal and Installation" (center pillar lower garnish) and INT-26, "DASH SIDE FINISHER : Removal and Installation" (dash side finisher).

- Pull up floor carpet. Refer to INT-35, "Removal and Installation".

- Disconnect G sensor harness connector.

- Remove G sensor.

- Remove bracket.

INSTALLATION

Installation is the reverse order of removal.

Adjustment

ADJUSTMENT AFTER INSTALLATION

Perform “CALIBRATION OF G SENSOR”. Refer to TM-147, "Description".

AIR Breather hose

AIR Breather hose

Exploded View

Harness bracket

Clip

Air breather hose

Vehicle front

Always replace after every

disassembly.

Removal and Installation

REMOVAL

Remove clips from harness bracke ...

OIL PAN

OIL PAN

Exploded View

Transaxle assembly

Oil pan gasket

Magnet

Oil pan

Overflow tube

Drain plug gasket

Drain plug

Oil pan fitting bolt

: Always replace after every

disassembly.

: ...

Other materials:

B0098 Front door satellite sensor RH

Description

DTC B0098 FRONT DOOR SATELLITE SENSOR RH

The front door satellite sensor RH is wired to the air bag diagnosis sensor

unit. The air bag diagnosis sensor

unit will monitor the front door satellite sensor RH for internal failures and

its circuits for communication errors.

PART LOCA ...

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT

BELT PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver and front passenger for certain

types of collision. Information necessary to service the system ...

NISSAN Intelligent Key® (if so equipped)

WARNING

Radio waves could adversely affect

electric medical equipment. Those who

use a pacemaker should contact the

electric medical equipment manufacturer

for the possible influences before

use.

The Intelligent Key transmits radio

waves when the buttons are pr ...