Nissan Sentra Service Manual: Flywheel

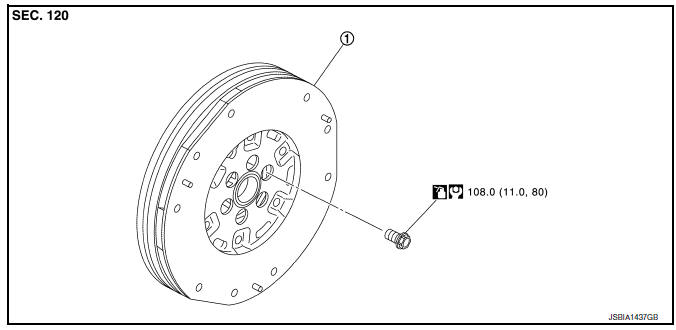

Exploded View

- Flywheel

Removal and Installation

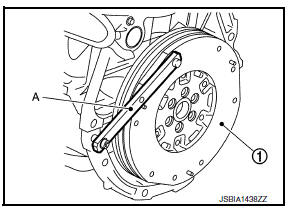

REMOVAL

- Remove the engine and the transaxle assembly from the vehicle, and separate the transaxle from the engine. Refer to TM-28, "Exploded View".

- Remove flywheel.

- Secure flywheel (1) using Tool (A), and remove bolts using suitable tool.

Tool number : KV11105210 (J-44716)

CAUTION:

- Do not disassemble flywheel.

- Do not place flywheel with signal plate facing down.

- When handling signal plate, take care not to damage or scratch.

- Handle signal plate, do so in a manner that prevents it from becoming magnetized.

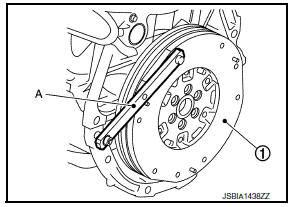

INSTALLATION

- Install flywheel.

- Secure flywheel (1) using Tool (A), and install bolts.

Tool number : KV11105210 (J-44716)

CAUTION:

Be careful not to damage or scratch the contact surface of flywheel.

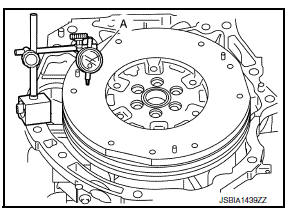

Inspection

FLYWHEEL DEFLECTION

- Measure the deflection of flywheel contact surface to torque with a dial indicator (A).

- Measure the deflection at 210 mm (8.27 in) diameter.

Limit : 0.45 mm (0.0177 in) or less.

- If measured value is out of the standard, replace flywheel.

- If a trace of burn or discoloration is found on the surface, repair it with sandpaper.

MOVEMENT AMOUNT OF FLYWHEEL

CAUTION:

Do not disassemble double mass flywheel.

Movement Amount of Thrust (Fore-and-Aft) Direction

- Measure the movement amount of thrust (fore-and-aft) direction when 100 N (10.2 kg, 22 lb) force is added at the portion of 125 mm (4.92 in) radius from the center of flywheel.

Standard : 1.8 mm (0.071 in) or less

- If measured value is out of the standard, replace flywheel

Movement Amount in Radial (Rotation) Direction

Check the movement amount of radial (rotation) direction with the following procedure:

- Install clutch cover bolt (1) to clutch cover hole, and place a torque wrench (A) on the extended line of the flywheel (2) center line.

- Tighten bolt at a force of 9.8 NВ·m (1.0 kg-m, 87 in-lb) to keep it from loosening.

- Put a mating mark on circumferences of the two flywheel masses without applying any load (Measurement standard points).

- Apply a force of 9.8 NВ·m (1.0 kg-m, 87 in-lb) in each direction, and mark the movement amount on the mass on the transaxle side.

- Measure the dimensions of movement amounts (A) and (B) on circumference of the flywheel on the transaxle side.

Limit : 33.2 mm (1.307 in) or less.

- If measured value is out of the standard, replace flywheel.

Drive plate

Drive plate

Exploded View

Pilot converter

Drive plate

Reinforcement plate

Chamfered

Removal and Installation

REMOVAL

Remove the engine and the transaxle assembly from the vehicle, and

...

Other materials:

System description

Component parts

Component parts location

ABS actuator and electric unit (control

unit)

Av control unit

A/c auto amp.

Ecm

Ipdm e/r

Tcm

Data link connector

EPS control unit

Bcm

Combination meter

Steering angle sensor

Air bag diagnosis sensor unit

System

Can communi ...

Diagnosis system (ECM)

Diagnosis description : 1st trip detection

logic and two trip detection logic

When a malfunction is detected for the first time, 1st trip DTC and 1st trip

Freeze Frame data are stored in the

ECM memory. The MIL will not illuminate at this stage. <1st trip>

If the same malfunction is dete ...

Precaution for Supplemental Restraint System (SRS) "AIR BAG"

and "SEAT BELT PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT

BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver and front passenger for certain

types of collision. Information necessary to service the system ...