Nissan Sentra Service Manual: Camshaft

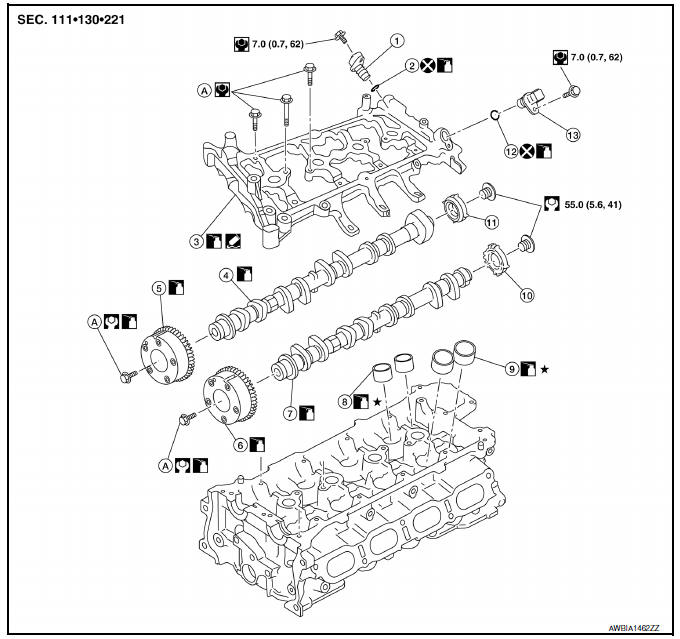

Exploded View

- Camshaft position sensor (EXH)

- O-ring

- Camshaft bracket

- Camshaft (EXH)

- Camshaft sprocket (EXH)

- Camshaft sprocket (INT)

- Camshaft (INT)

- Valve lifter (EXH)

- Valve lifter (INT)

- Signal plate (INT)

- Signal plate (EXH)

- O-ring

- Camshaft position sensor (INT)

A. Refer to INSTALLATION

Removal and Installation

CAUTION:

The rotating direction is shown from the engine front.

REMOVAL

- Remove intake manifold. Refer to EM-27, "Exploded View".

- Remove rocker cover. Refer to EM-12, "Exploded View".

- Remove timing chain. Refer to EM-48, "Exploded View".

NOTE:

Removal of oil pump drive related part is not necessary.

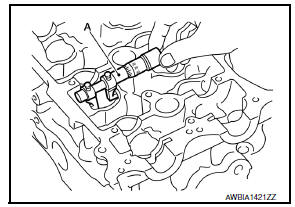

- Remove camshaft position sensor (INT) and camshaft position sensor (EXH) from camshaft bracket.

CAUTION:

- Handle camshaft position sensor (INT) and camshaft position sensor (EXH) carefully and avoid impacts.

- Do not disassemble camshaft position sensor (INT) and camshaft position sensor (EXH).

- Do not place sensor where it is exposed to magnetism.

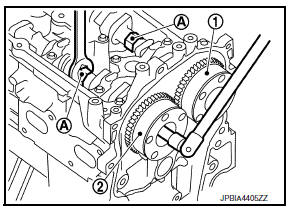

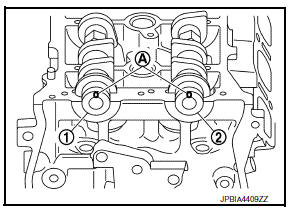

- Put painted matching mark (A) on the camshaft sprocket (INT) (2), camshaft sprocket (EXH) (3) and the camshaft bracket (1) as shown.

NOTE:

When camshaft alignment is as show in installation, it prevents the knock pin of the camshaft (INT) from engaging with the incorrect pin hole when installing the camshaft sprocket (INT).

- Remove camshaft sprockets (INT and EXH).

- Secure hexagonal part (A) of camshaft using suitable tool.

Loosen camshaft sprocket bolts and remove camshaft sprocket.

(1) : Camshaft sprocket (INT)

(2) : Camshaft sprocket (EXH)

CAUTION:

- Do not rotate crankshaft or camshaft while timing chain is removed. It causes interference between valve and piston.

- Do not loosen the bolts with securing anything other than the camshaft hexagonal part.

- Remove camshaft bracket with the following procedure:

- Loosen bolts in reverse order as shown.

- Cut liquid gasket by prying the position (

) shown using suitable

) shown using suitable

tool, and then remove the camshaft bracket.

CAUTION:

- Do not damage the mating surface.

- Do not use suitable tool anywhere other than shown, sealant used is more adhesive than previous types when shipped.

- Remove camshafts.

- Remove valve lifters, if necessary

- Identify installation positions, and store them without mixing them up.

- Remove signal plate from camshaft, if necessary.

INSTALLATION

CAUTION:

Do not reuse O-rings.

- Install valve lifters.

- Install them in the original positions.

- Install camshafts.

- Clean camshaft journal to remove any foreign material.

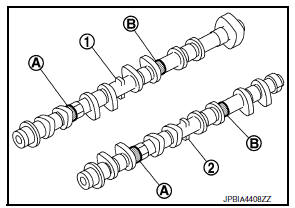

- Distinguish between the intake and the exhaust by looking at the different shapes of the front and rear ends of the camshaft or using the identification colors (A) and (B).

(1) : Camshaft (EXH)

(2) : Camshaft (INT)

- Install camshafts so that camshaft dowel pins (A) on the front side are positioned as shown.

NOTE:

Though camshaft does not stop at the positions as shown, for the placement of cam nose, it is generally accepted camshaft is placed for the same direction as shown.

- Install camshaft bracket with the following procedure:

- Remove foreign material completely from camshaft bracket backside and from cylinder head installation face.

- Apply liquid gasket (A) to camshaft bracket as shown.

(b) : Plug hole inner wall

(c) : 3.4 - 4.4 mm (0.134 - 0.173 in)

Use Genuine Silicone RTV Sealant, or equivalent. Refer to GI-21, "Recommended Chemical Products and Sealants".

CAUTION:

- Installation should be done within 5 minutes after applying liquid gasket

- Do not fill the engine with oil for at least 30 minutes after the components are installed to allow the sealant to cure.

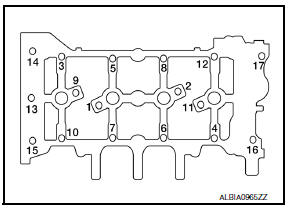

- Tighten bolts of camshaft brackets in the following steps, in numerical order as shown.

- There are two types of bolts. Refer to the following for locating bolts.

![M6 bolts [thread length: 57.5 mm (2.264 in)]](images/books/349/4/index15.jpg)

M6 bolts [thread length: 57.5 mm (2.264 in)] : 13, 14, and 15

M6 bolts [thread length: 35.0 mm (1.378 in)] : Except the above

- Tighten bolts to the specified torque in three steps in the order as shown.

Step 1 : 1.96 NВ·m (0.20 kg-m, 17 in-lb)

Step 2 : 5.88 NВ·m (0.60 kg-m, 52 in-lb)

Step 3 : 9.5 NВ·m (0.97 kg-m, 84 in-lb)

CAUTION:

After tightening bolts of camshaft bracket, be sure to wipe off excessive liquid gasket from the mating surface of cylinder head.

- Install the camshaft sprocket to the camshaft with the following procedure.

- When the camshaft sprocket (INT) (2) and camshaft sprocket (EXH) (3) is installed, refer to the paint matching marks (A) made during removal. Securely align the knock pin and the pin hole, and then install them.

- Tighten bolts in the following steps.

- Secure the hexagonal part of camshaft using suitable tool to tighten bolt.

CAUTION:

Check the tightening angle using Tool (B). Do not judge by visual inspection.

Step 1 : 35.0 NВ·m (3.6 kg-m, 26 ft-lb)

Step 2 : 30.5 degrees rotation

Tool number : KV10112100 (BT-8653-A)

(1) : Camshaft sprocket

(A) : Camshaft hexagonal part

- Install timing chain. Refer to EM-48, "Exploded View".

- Inspect and adjust valve clearance. Refer to EM-20, "Inspection and Adjustment".

- Installation of remaining components is in the reverse order of removal.

Inspection

INSPECTION AFTER REMOVAL

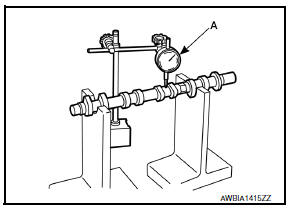

Camshaft Runout

- Put V-block on a precise flat table, and support No. 2 and 5 journal of camshaft.

CAUTION:

Do not support No. 1 journal (on the side of camshaft sprocket) because it has a different diameter from the other four locations.

- Set suitable tool (A) vertically to No. 3 journal.

- Turn camshaft to one direction with hands, and measure the camshaft runout on dial indicator. (Total indicator reading)

Standard and Limit : Refer to EM-119, "Camshaft".

- If it exceeds the limit, replace camshaft.

Camshaft Cam Height

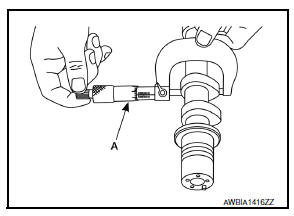

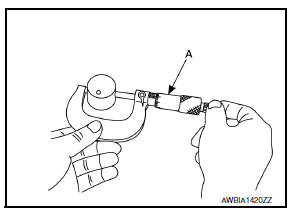

- Measure the camshaft cam height using suitable tool (A).

Standard and Limit : Refer to EM-119, "Camshaft".

- If it exceeds the limit, replace camshaft.

Camshaft Journal Oil Clearance

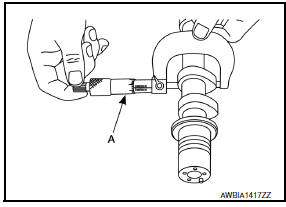

CAMSHAFT JOURNAL OUTER DIAMETER

Measure the outer diameter of camshaft journal using suitable tool (A).

Standard : Refer to EM-119, "Camshaft".

If it exceeds the limit, replace camshaft.

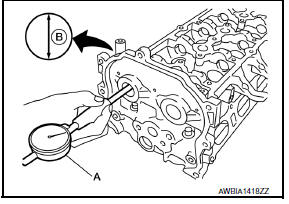

CAMSHAFT BRACKET INNER DIAMETER

- Tighten camshaft bracket bolts with specified torque. Refer to EM-60, "Removal and Installation".

- Measure the inner diameter of camshaft bracket using suitable tool (A).

(B) : Measuring direction of inner diameter

Standard : Refer to EM-119, "Camshaft".

- If it exceeds limit, replace camshaft bracket.

CAMSHAFT JOURNAL OIL CLEARANCE

- (Oil clearance) = (Camshaft bracket inner diameter) – (Camshaft journal diameter)

Standard and Limit : Refer to EM-119, "Camshaft".

- If it exceeds the limit, replace camshaft or cylinder head, or both.

NOTE:

Camshaft bracket cannot be replaced as a single part, because it is machined together with cylinder head.

Replace cylinder head assembly.

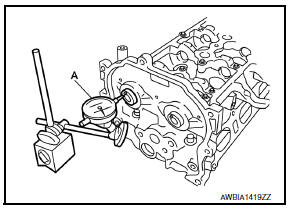

Camshaft End Play

- Install camshaft in cylinder head. Refer to EM-60, "Removal and Installation".

- Install suitable tool in thrust direction on front end of camshaft.

Read the end play on suitable tool (A) when camshaft is moved forward/backward (in direction to axis).

Standard and Limit : Refer to EM-119, "Camshaft".

- Measure the following parts if out of the standard.

- Dimension (A) for groove of cylinder head No. 1 journal

Standard : 4.000 - 4.030 mm (0.1575 - 0.1587 in)

- Dimension (B) for camshaft flange

Standard : 3.877 - 3.925 mm (0.1526 - 0.1545 in)

- Refer to the standards above, and then replace camshaft and/ or cylinder head.

Camshaft Sprocket Runout

- Put V-block on precise flat table, and support No. 2 and 5 journals of camshaft.

CAUTION:

Do not support No. 1 journal (on the side of camshaft sprocket) because it has a different diameter from the other four locations.

- Measure the camshaft sprocket runout using suitable tool (A).

(Total indicator reading)

Limit : Refer to EM-119, "Camshaft".

- If it exceeds the limit, replace camshaft sprocket.

Valve Lifter

Check if surface of valve lifter has any wear or cracks.

- If anything above is found, replace valve lifter. Refer to EM-119, "Camshaft".

Valve Lifter Clearance

VALVE LIFTER OUTER DIAMETER

- Measure the outer diameter of valve lifter using suitable tool (A).

Standard : Refer to EM-119, "Camshaft".

VALVE LIFTER HOLE DIAMETER

Measure the inner diameter of valve lifter hole of cylinder head using suitable tool (A).

Standard : Refer to EM-119, "Camshaft".

VALVE LIFTER CLEARANCE

- (Valve lifter clearance) = (Valve lifter hole diameter) – (Valve lifter outer diameter)

Standard : Refer to EM-119, "Camshaft".

- If out of the standard, referring to the each standard of valve lifter outer diameter and valve lifter hole diameter, replace either or both valve lifter and cylinder head.

INSPECTION AFTER INSTALLATION

Inspection of Camshaft Sprocket (INT), (EXH) Oil Groove

WARNING:

Check when engine is cold so as to prevent burns by the splashing engine oil.

CAUTION:

Perform this inspection only when DTC P0011 or P0014 is detected in self-diagnostic results of CONSULT and it is directed according to inspection procedure of EC section. Refer to EC-171, "Diagnosis Procedure" (P0011) or EC-174, "Diagnosis Procedure" (P0014).

- Check engine oil level. Refer to LU-7, "Inspection".

- Perform the following procedure so as to prevent the engine from being unintentionally started while checking.

- Release the fuel pressure. Refer to EC-143, "Work Procedure".

- Remove intake manifold. Refer to EM-27, "Exploded View".

- Disconnect ignition coil and injector harness connectors.

- Support the bottom surface of engine using a transmission jack, and then remove the engine mounting bracket (RH) and engine mounting insulator (RH). Refer to EM-82, "M/T : Exploded View".

- Remove intake or exhaust valve timing control solenoid valve. Refer to EM-48, "Exploded View".

- Lift the front side of the engine with a jack base to remove intake or exhaust valve timing control solenoid valve.

- Clean the mounting area of intake or exhaust valve timing control solenoid valve, and then insert a clean shop cloth with no oil adhesion into the oil hole of the cylinder head.

- Install engine mounting insulator (RH) and engine mounting bracket (RH). (After the removal of intake or exhaust valve timing control solenoid valve and insertion of a shop cloth into the oil hole.)

- Perform cranking to check that engine oil comes out from the oil hole (mounting hole of intake or exhaust valve timing control solenoid valve) of cylinder head.

- Regarding the engine oil check, judge it by the amount of oil adhered to the shop cloth inserted into the oil hole.

WARNING:

- Do not insert fingers into the oil hole.

- Be careful not to touch rotating parts (drive belt, idler pulleys and crankshaft pulley, etc.).

CAUTION:

- Do not perform cranking without installing the engine mounting insulator (RH) and engine mounting bracket (RH).

- Prevent splashing by using a shop cloth so as to prevent the worker from injury from engine oil and so as to prevent engine oil contamination.

- Prevent splashing by using a shop cloth so as to prevent engine oil from being splashed to engine and vehicle. Especially, be careful not to apply engine oil to rubber parts of drive belt, engine mounting insulator, etc. Wipe engine oil off immediately if it is splashed.

- Perform the following inspection if engine oil does not come out from intake or exhaust valve timing control solenoid valve oil hole of the cylinder head.

- Clean oil groove between oil strainer and intake valve timing control solenoid valve. Refer to LU-6, "Engine Lubrication System Schematic".

- Remove components between intake or exhaust valve timing control solenoid valve and camshaft sprocket (INT) or (EXH), and then check each oil groove for clogging.

- Clean oil groove if necessary. Refer to LU-6, "Engine Lubrication System Schematic".

- Installation of remaining components is in the reverse order of removal.

Timing chain

Timing chain

Exploded View

Timing chain slack guide

Timing chain tensioner

Timing chain

Oil pump drive chain

Crankshaft sprocket

Crankshaft key

Oil pump sprocket

Front cover

O-ring

O-ring ...

Oil seal

Oil seal

Valve oil seal : Removal and Installation

REMOVAL

Rotate crankshaft, and set piston whose valve oil seal is to be removed

to TDC. This will prevent valve

from dropping into cylinder.

CAUT ...

Other materials:

Timing chain

Exploded View

Timing chain slack guide

Timing chain tensioner

Timing chain

Oil pump drive chain

Crankshaft sprocket

Crankshaft key

Oil pump sprocket

Front cover

O-ring

O-ring

Valve timing control solenoid valve cover

O-ring

Valve timing control solenoid valve

(EXH)

...

ECU diagnosis information

TCM

Reference Value

CONSULT DATA MONITOR STANDARD VALUE

NOTE:

The following table includes information (items) inapplicable to this

vehicle. For information (items) applicable

to this vehicle, refer to CONSULT display items.

In CONSULT, electric shift timing or lock-up timing, i.e. op ...

Air fresheners

Most air fresheners use a solvent that could affect

the vehicle interior. If you use an air freshener,

take the following precautions:

Hanging-type air fresheners can cause permanent

discoloration when they contact vehicle

interior surfaces. Place the air freshener

in a location that all ...