Nissan Sentra Service Manual: C1601 Battery power supply

DTC Logic

DTC DETECTION LOGIC

| DTC | Display item | Malfunction detected condition | Possible cause |

| C1601 | BATTERY VOLT | When a power supply voltage to the EPS control unit is maintained at 17.5 V or more or at less than 9 V continuously for five second or more. |

|

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC CONFIRMATION PROCEDURE has been previously conducted, always turn ignition switch OFF and wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.DTC REPRODUCTION PROCEDURE

With CONSULT

With CONSULT

-

Turn the ignition switch OFF to ON.

-

Perform EPS self-diagnosis.

Is DTC C1601 detected? YES >> Proceed to diagnosis procedure. Refer to STC-22, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis Procedure

Regarding Wiring Diagram information, refer to STC-15, "Wiring Diagram".

1.Check EPS Control unit ground circuit

-

Turn ignition switch OFF.

-

Disconnect EPS control unit harness connector.

-

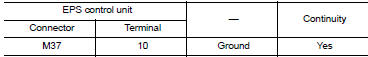

Check continuity between EPS control unit harness connector terminal and ground.

-

Connect EPS control unit harness connector.

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

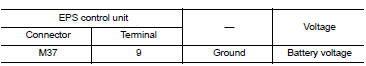

2.Check EPS Control unit power supply circuit (1)

-

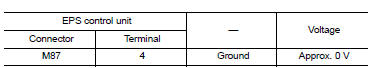

Check voltage between EPS control unit harness connector terminals and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 3.

3.Check EPS Control unit power supply circuit

(2)

-

Turn ignition switch OFF.

-

Check the 10A fuse (#5).

-

Check the harness for open or short between EPS control unit harness connector terminal 4 and the 10A fuse (#5).

Is the inspection result normal? YES >> Perform the trouble diagnosis for ignition power supply circuit. Refer to PCS-70, "Wiring Diagram".

NO >> Repair or replace the malfunctioning parts.

4.Check EPS Control unit power supply circuit (3)

-

Turn ignition switch OFF.

-

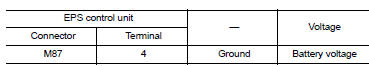

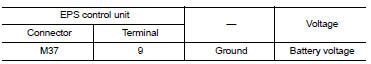

Check voltage between EPS control unit harness connector terminals and ground.

-

Turn ignition switch ON.

CAUTION:

Never start the engine.

-

Check voltage between EPS control unit harness connector and ground.

Is the inspection result normal? YES >> GO TO 6.

NO >> GO TO 5.

5.CHECK EPS CONTROL UNIT POWER SUPPLY CIRCUIT (4)

-

Turn ignition switch OFF.

-

Check the 60A fusible link (#M).

-

Check the harness for open or short between EPS control unit harness connector terminal 9 and the 60A fusible link (#M).

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit. Refer to PCS-70, "Wiring Diagram".

NO >> Repair or replace the malfunctioning parts.

6.CHECK TERMINALS AND HARNESS CONNECTORS

Check the EPS control unit pin terminals for damage or loose connection with harness connector.

Is the inspection result normal? YES >> EPS control unit is malfunctioning. Replace steering column assembly. Refer to ST-12, "Removal and Installation".

NO >> Repair or replace the malfunctioning parts.

C1604 Torque sensor

C1604 Torque sensor

DTC Logic

DTC DETECTION LOGIC

DTC

Display item

Malfunction detected condition

Possible cause

C1604

TORQUE SENSOR

When torque sensor output signal is malfunctioning

...

Other materials:

Diagnosis system (TCM)

DIAGNOSIS DESCRIPTION

DIAGNOSIS DESCRIPTION : 1 Trip Detection Diagnosis and 2 Trip Detection

Diagnosis

NOTE:

“Start the engine and turn OFF the ignition switch after warm-up.” This is

defined as 1 trip.

TRIP DETECTION DIAGNOSIS

When initial malfunction is detected, TCM mem ...

Precaution

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT

BELT PRE-TENSIONER"

The supplemental restraint system such as “air bag” and “seat belt pre-tensioner”,

used along

with a front seat belt, helps to reduce the risk or severity of injur ...

C1121, C1123, C1125, C1127 ABS OUT Valve system

DTC Logic

DTC DETECTION LOGIC

DTC DETECTION LOGIC

Display Item

Malfunction detected condition

Possible causes

C1121

FR LH OUT ABS SOL

When a malfunction is detected in front LH ABS OUT

valve.

Harness or connector

ABS actuator and electric unit

...