Nissan Sentra Service Manual: Brake pedal

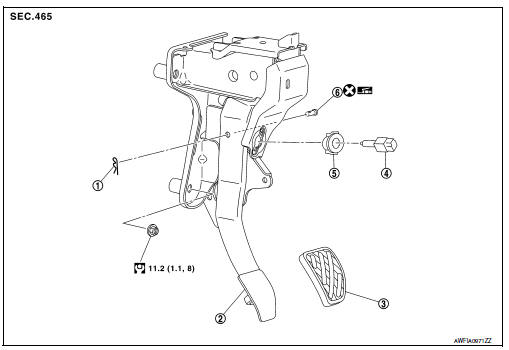

Exploded View

WITHOUT BRAKE PEDAL POSITION SWITCH

- Snap pin

- Brake pedal assembly

- Brake pedal pad

- Stop lamp switch

- Clip

- Clevis pin

Apply multi-purpose grease.

Apply multi-purpose grease.

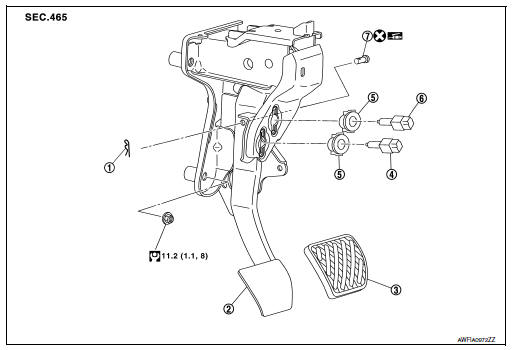

WITH BRAKE PEDAL POSITION SWITCH

- Snap pin

- Brake pedal assembly

- Brake pedal pad

- Brake pedal position switch

- Clip

- Stop lamp switch

Apply multi-purpose grease.

Apply multi-purpose grease.

Removal and Installation

REMOVAL

- Remove instrument lower panel LH. Refer to IP-21, "Removal and Installation".

- Remove steering column lower cover. Refer to IP-16, "Removal and Installation".

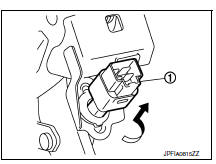

- Disconnect the harness connectors from the brake pedal position switch (if equipped) and the stop lamp switch.

- Rotate the stop lamp switch and the brake pedal position switch (if equipped) (1) counter clockwise to remove.

- Disconnect the accelerator pedal harness connector and harness clip.

- Remove snap pin and clevis pin from clevis on brake booster.

- Remove the brake pedal assembly.

CAUTION:

Secure the brake booster and brake master cylinder to avoid damage to components.

- Remove accelerator pedal from brake pedal assembly. Refer to ACC-3, "Removal and Installation".

INSPECTION AFTER REMOVAL

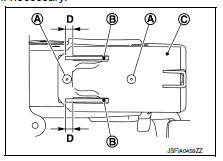

Check for the following items and replace the brake pedal assembly, if necessary.

- Check the brake pedal upper rivet (A) for damage or wear.

- Check the brake pedal for bend, damage, and cracks on the welded parts.

- Check the lapping length (D) of sub-bracket (B) and slide plate (C).

Lapping length (D) : 6.5 mm (0.256 in) or more

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Do not reuse the clevis pin.

- Install the clevis pin in the proper direction. Refer to BR-22, "Exploded View".

- Apply multi-purpose grease to the clevis pin and the mating faces, if necessary.

ADJUSTMENT AFTER INSTALLATION

- Adjust each item of brake pedal after installing the brake pedal assembly to the vehicle. Refer to BR-15, "Adjustment".

- Perform the release position learning of the accelerator pedal. Refer to EC-138, "Work Procedure".

Brake piping

Brake piping

FRONT

FRONT : Exploded View

Brake tube

ABS actuator and electric unit (control

unit)

Connector

Connector bracket

Master cylinder assembly

Brake booster

Lock plate

Brake hose

...

Other materials:

Rear drum brake

BRAKE LINING

BRAKE LINING : Inspection

INSPECTION

Brake Lining

Check brake lining wear thickness (A). Check using a scale if

necessary.

Lining wear thickness (A) : Refer to BR-55, "Rear

Drum Brake".

BRAKE DRUM

BRAKE DRUM : Inspection

INSPECTION

Appearance

Check surfac ...

B terminal circuit

Description

“B” terminal circuit supplies power to charge the battery and to operate the

vehicles electrical system.

Diagnosis procedure

Regarding wiring diagram information. Refer to chg-9, "wiring diagram".

1.Check “b” terminal connection

Turn ignition switc ...

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT

BELT PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver and front passenger for certain

types of collision. Information necessary to service the system ...