Nissan Sentra Service Manual: Basic inspection

Diagnosis and repair workflow

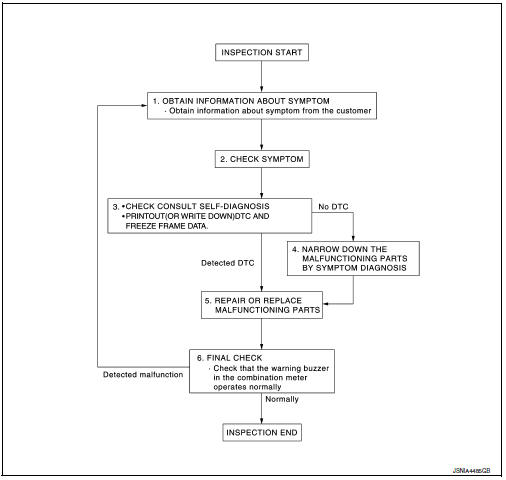

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1.OBTAIN INFORMATION ABOUT SYMPTOM

Interview the customer to obtain as much information as possible about the conditions and environment under which the malfunction occurred.

>> GO TO 2.

2.CHECK SYMPTOM

- Check the symptom based on the information obtained from the customer.

- Check if any other malfunctions are present.

>> GO TO 3.

3.CHECK CONSULT SELF-DIAGNOSIS RESULTS

Connect CONSULT and perform self-diagnosis. Refer to MWI-26, "DTC Index".

Are self-diagnosis results normal? YES >> GO TO 4.

NO >> GO TO 5.

4.NARROW DOWN MALFUNCTIONING PARTS BY SYMPTOM DIAGNOSIS

Perform symptom diagnosis and narrow down the malfunctioning parts.

>> GO TO 5.

5.REPAIR OR REPLACE MALFUNCTIONING PARTS

Repair or replace malfunctioning parts.

NOTE:

If DTC is displayed, erase DTC after repairing or replacing malfunctioning parts.

>> GO TO 6.

6.FINAL CHECK

Check that the warning buzzer in the combination meter operates normally.

Does it operate normally? YES >> Inspection End.

NO >> GO TO 1.

Wiring diagram

Wiring diagram

Warning chime system

Wiring diagram

...

Other materials:

Child safety rear door lock

Child safety locks help prevent the rear doors

from being opened accidentally, especially when

small children are in the vehicle.

The child safety lock levers are located on the

edge of the rear doors.

When the lever is in the unlock position 2 , the

door can be opened from the outside ...

Changing wheels and tires

Tire rotation

NISSAN recommends rotating the tires

every 7,500 miles (12,000 km).

See “Flat tire” in the “In case of emergency”

section of this manual for tire replacing

procedures.

As soon as possible, tighten the

wheel nuts to the specified torque

with a torque wrench.

Wheel ...

U1002 System comm (CAN)

DTC Logic

DTC DETECTION LOGIC

DTC

Display item

Malfunction detected condition

Possible cause

U1002

SYSTEM COMM(CAN)

When ABS actuator and electric unit (control unit) is not

transmitting or receiving CAN communication signal for 2

seconds or less.

C ...