Nissan Sentra Service Manual: Basic inspection

Diagnosis and repair workflow

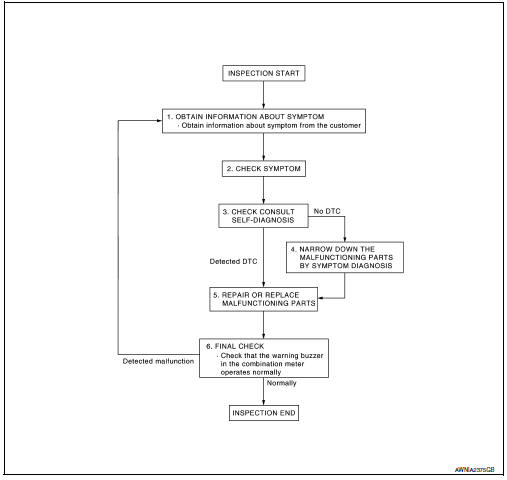

Work flow

Overall sequence

Detailed flow

1.Obtain information about symptom

Interview the customer to obtain as much information as possible about the conditions and environment under which the malfunction occurred.

>> GO TO 2.

2.Check symptom

- Check the symptom based on the information obtained from the customer.

- Check if any other malfunctions are present.

>> Go to 3.

3.Check consult self-diagnosis results

Connect consult and perform self-diagnosis. Refer to mwi-26, "dtc index".

Are self-diagnosis results normal? Yes >> go to 4.

No >> go to 5.

4.Narrow down malfunctioning parts by symptom diagnosis

Perform symptom diagnosis and narrow down the malfunctioning parts.

>> Go to 5.

5.Repair or replace malfunctioning parts

Repair or replace malfunctioning parts.

Note:

If dtc is displayed, erase dtc after repairing or replacing malfunctioning parts.

>> Go to 6.

6.Final check

Check that the warning buzzer in the combination meter operates normally.

Does it operate normally? Yes >> inspection end.

No >> go to 1.

Wiring diagram

Wiring diagram

Meter system

Wiring diagram

Compass

Wiring diagram

...

Other materials:

Power supply and ground circuit

Diagnosis procedure

Regarding wiring diagram information, refer to bcs-51, "wiring diagram".

1.Check fuses and fusible link

Check that the following fuses and fusible link are not blown.

Is the fuse blown?

YES >> Replace the blown fuse or fusible link after repairing the aff ...

The light reminder warning does

not sound

Description

Light reminder warning chime does not sound even though headlamp is

illuminated.

Diagnosis procedure

1.Check combination meter input signal

Select the data monitor for the meter/m&a and check the buzzer monitor value.

Is the inspection result normal?

Yes >> replace ...

Low tire pressure warning lamp

Component Function Check

1.CHECK THE ILLUMINATION OF THE LOW TIRE PRESSURE WARNING LAMP

Check that the low tire pressure warning lamp is turned OFF after

illuminating for approximately 1 second,

when the ignition switch is turned ON.

Is the inspection result normal?

YES >> Inspection ...