Nissan Sentra Service Manual: Basic inspection

Diagnosis and repair workflow

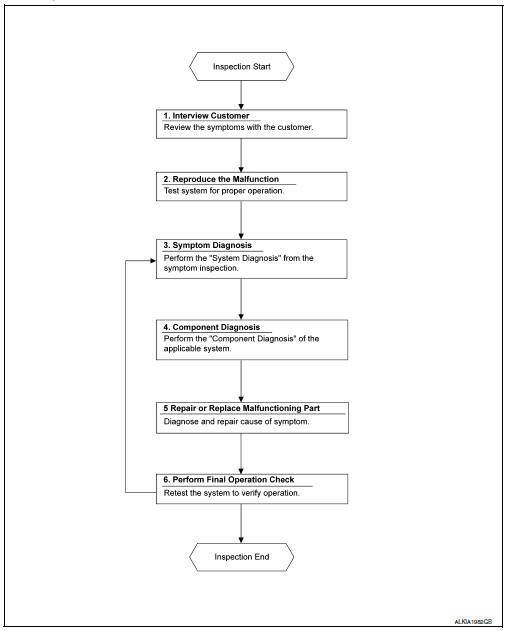

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1. OBTAIN INFORMATION ABOUT SYMPTOM

Interview the customer to obtain as much information as possible about the conditions and environment under which the malfunction occurred.

>> GO TO 2.

2. CONFIRM THE SYMPTOM

Check the malfunction on the vehicle that the customer describes.

Inspect the relation of the symptoms and the condition when the symptoms occur.

>> GO TO 3.

3. IDENTIFY THE MALFUNCTIONING SYSTEM WITH SYMPTOM DIAGNOSIS

Use Symptom diagnosis from the symptom inspection result in step 2 and then identify where to start performing the diagnosis based on possible causes and symptoms. Refer to WW-46, "Symptom Table".

>> GO TO 4.

4. PERFORM THE COMPONENT DIAGNOSIS OF THE OF THE APPLICABLE SYSTEM

Perform the diagnosis with Component diagnosis of the applicable system.

>> GO TO 5.

5. REPAIR OR REPLACE THE MALFUNCTIONING PARTS

Repair or replace the specified malfunctioning parts.

>> GO TO 6.

6. FINAL CHECK

Check that malfunctions are not reproduced when obtaining the malfunction information from the customer, referring to the symptom inspection result in step 2.

Are the malfunctions corrected? YES >> Inspection End.

NO >> GO TO 3.

Wiring diagram

Wiring diagram

Wiper and washer system

Wiring diagram - with intelligent key

Wiring diagram - without intelligent key

...

Other materials:

Symptom diagnosis

Nissan vehicle immobilizer systemnats

symptoms

Symptom Table

Note:

Before performing the diagnosis in the following table, check

“SEC-171, "Work Flow"”.

Check that vehicle is under the condition shown in “Conditions of

vehicle” before starting diagnosis, ...

Basic inspection

Diagnosis and repair workflow

Trouble diagnosis flow chart

Trouble diagnosis procedure

Interview with customer

Interview with the customer is important to detect the root cause of can

communication system errors and to

understand vehicle condition and symptoms for proper trouble diagnosi ...

Manual operation

Fan speed control

Press the fan control buttons to

manually

control the fan speed.

Press the AUTO button to return to automatic

control of the fan speed.

Air recirculation

Press the air recirculation

button to recirculate

interior air inside the vehicle. The

indicator light on the b ...