Nissan Sentra Service Manual: Basic inspection

Diagnosis and repair workflow

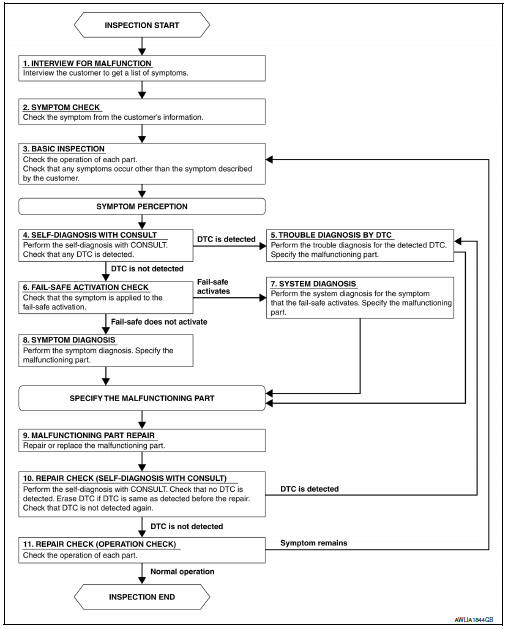

Work flow

OVERALL SEQUENCE

DETAILED FLOW

1.INTERVIEW FOR MALFUNCTION

Find out what the customer's concerns are.

>> GO TO 2.

2.SYMPTOM CHECK

Verify the symptom from the customer's information.

>> GO TO 3.

3.BASIC INSPECTION

Check the operation of each part. Check that any concerns occur other than those mentioned in the customer interview.

>> GO TO 4.

4.SELF-DIAGNOSIS WITH CONSULT

Perform the self-diagnosis with CONSULT. Check that any DTC is detected.

Is any DTC detected? YES >> GO TO 5.

NO >> GO TO 6.

5.TROUBLE DIAGNOSIS BY DTC

Perform the trouble diagnosis for the detected DTC. Specify the malfunctioning part.

>> GO TO 9.

6.FAIL-SAFE ACTIVATION CHECK

Determine if the customer's concern is related to fail-safe activation.

Does the fail-safe activate? YES >> GO TO 7.

NO >> GO TO 8.

7.SYSTEM DIAGNOSIS

Perform the system diagnosis for the system in which the fail-safe activates. Specify the malfunctioning part.

>> GO TO 9.

8.SYMPTOM DIAGNOSIS

Perform the symptom diagnosis, refer to INL-51, "Symptom Table". Specify the malfunctioning part.

>> GO TO 9.

9.MALFUNCTION PART REPAIR

Repair or replace the malfunctioning part.

>> GO TO 10.

10.REPAIR CHECK (SELF-DIAGNOSIS WITH CONSULT)

Perform the self-diagnosis with CONSULT. Verify that no DTCs are detected. Erase all DTCs detected prior to the repair. Verify that DTC is not detected again.

Is any DTC detected? YES >> GO TO 5.

NO >> GO TO 11.

11.REPAIR CHECK (OPERATION CHECK)

Check the operation of each part.

Does it operate normally? YES >> Inspection End.

NO >> GO TO 3.

Wiring diagram

Wiring diagram

Interior room lamp control system

Wiring diagram

Illumination

Wiring diagram

...

Other materials:

Removal and installation

A/C SWITCH ASSEMBLY

Removal and Installation

REMOVAL

Remove the CVT shift selector finisher (CVT: RE0F11A). Refer to TM-253,

"Removal and Installation".

Remove the MT shift selector finisher (6MT: RS6F94R). Refer to TM-22,

"Removal and Installation".

Remove the A/ ...

Tire labeling

Federal law requires tire manufacturers to

place standardized information on the

sidewall of all tires. This information identifies

and describes the fundamental

characteristics of the tire and also provides

the tire identification number (TIN)

for safety standard certification. The TIN

can b ...

Battery terminal with fusible link

Exploded view

Battery terminal with fusible link

Harness connector

Removal and installation

Removal

Loosen the battery terminal nuts and disconnect both battery negative and

positive terminals. Refer to

pg-50, "exploded view".

Caution:

To prevent damage to the parts, di ...