Nissan Sentra Service Manual: P0443 EVAP Canister purge volume control solenoid valve

| DTC No. | CONSULT screen terms (Trouble diagnosis content) | DTC detecting condition | Possible cause | |

| P0443 | PURG VOLUME CONT/V (Evaporative emission system purge control valve circuit) | A | The canister purge flow is detected during the vehicle is stopped while the engine is running, even when EVAP canister purge volume control solenoid valve is completely closed. |

|

| B | The canister purge flow is detected during the specified driving conditions, even when EVAP canister purge volume control solenoid valve is completely closed. | |||

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

- Perform DTC CONFIRMATION PROCEDURE when the fuel is between 1/4 and 3/4 full, and vehicle is placed on flat level surface.

- Always perform test at a temperature of 5 to 60В°C (41 to 140В°F).

- Cool the vehicle so that engine coolant temperature becomes same level as ambient temperature.

Do you have CONSULT YES >> GO TO 2.

NO >> GO TO 4.

2.PERFORM DTC CONFIRMATION PROCEDURE A

With CONSULT

With CONSULT

- Turn ignition switch ON.

- Select “DATA MONITOR” mode of “ENGINE” using CONSULT.

- Check that the following condition are met.

FUEL T/TMP SE: 0 - 35В°C (32 - 95В°F)

- Start engine and wait at least 60 seconds.

- Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-294, "Diagnosis Procedure".

NO >> GO TO 3.

3.PERFORM DTC CONFIRMATION PROCEDURE B

With CONSULT

With CONSULT

- Start engine and warm it up to normal operating temperature.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Select “PURG VOL CN/V P1444” of “EVAPORATIVE SYSTEM” in “DTC WORK SUPPORT” mode of “ENGINE” using CONSULT.

- Touch “START”.

- Start engine and let it idle until “TESTING” on CONSULT changes to “COMPLETED”. (It will take approximately 10 seconds.)If “TESTING” is not displayed after 5 minutes, retry from step 2.

- Touch “SELF-DIAG RESULT”.

Which is displayed on CONSULT? OK >> INSPECTION END

NG >> Proceed to EC-294, "Diagnosis Procedure".

4.PERFORM DTC CONFIRMATION PROCEDURE A

With GST

With GST

- Turn ignition switch ON.

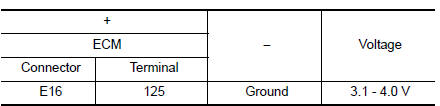

- Check the voltage between ECM harness connector and ground.

- Start engine and wait at least 60 seconds.

- Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-294, "Diagnosis Procedure".

NO >> GO TO 5.

5.PERFORM DTC CONFIRMATION PROCEDURE

With GST

With GST

- Start engine and warm it up to normal operating temperature.

- Turn ignition switch OFF and wait at least 10 seconds.

- Start engine and let it idle for at least 20 seconds.

- Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-294, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

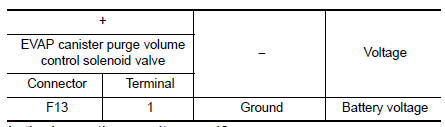

1.CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE POWER SUPPLY

- Turn ignition switch OFF.

- Disconnect EVAP canister purge volume control solenoid valve harness connector.

- Turn ignition switch ON.

- Check the voltage between EVAP canister purge volume control solenoid valve harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

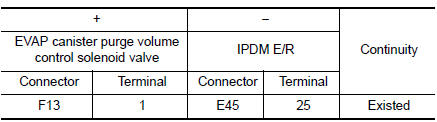

2.CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE POWER SUPPLY CIRCUIT

- Turn ignition switch OFF.

- Disconnect IPDM E/R harness connector.

- Check the continuity between EVAP canister purge volume control solenoid valve harness connector and IPDM E/R harness connector.

- Also check harness for short to ground.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

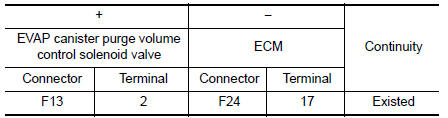

3.CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE GROUND CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Check the continuity between EVAP canister purge volume control solenoid valve harness connector and ECM harness connector.

- Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR CONNECTOR

- Disconnect EVAP control system pressure sensor harness connector.

- Check connectors for water.

Water should not exist.

Is the inspection result normal? YES >> GO TO 5.

NO >> Replace EVAP control system pressure sensor. Refer to FL-15, "Removal and Installation".

5.CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR

Check the EVAP control system pressure sensor. Refer to EC-296, "Component Inspection".

Is the inspection result normal? YES-1 >> With CONSULT: GO TO 6.

YES-2 >> Without CONSULT: GO TO 7.

NO >> Replace EVAP control system pressure sensor. Refer to FL-15, "Removal and Installation".

6.CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

With CONSULT

With CONSULT

- Turn ignition switch OFF.

- Reconnect harness connectors disconnected.

- Start engine.

- Perform “PURG VOL CONT/V” in “ACTIVE TEST” mode of “ENGINE” using CONSULT. Check that engine speed varies according to the valve opening.

Is the inspection result normal? YES >> GO TO 8.

NO >> GO TO 7.

7.CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

Check the EVAP canister purge volume control solenoid valve. Refer to EC-296, "Component Inspection".

Is the inspection result normal? YES >> GO TO 8.

NO >> Replace EVAP canister purge volume control solenoid valve. Refer to EM-27, "Exploded View".

8.CHECK RUBBER TUBE FOR CLOGGING

- Disconnect rubber tube connected to EVAP canister vent control valve.

- Check the rubber tube for clogging.

Is the inspection result normal? YES >> GO TO 9.

NO >> Clean the rubber tube using an air blower.

9.CHECK EVAP CANISTER VENT CONTROL VALVE

Check the EVAP canister vent control valve. Refer to EC-303, "Component Inspection".

Is the inspection result normal? YES >> GO TO 10.

NO >> Replace EVAP canister vent control valve. Refer to FL-15, "Removal and Installation".

10.CHECK IF EVAP CANISTER IS SATURATED WITH WATER

- Remove EVAP canister with EVAP canister vent control valve and EVAP control system pressure sensor attached.

- Check if water will drain from EVAP canister.

Does water drain from the EVAP canister? YES >> GO TO 11.

NO >> Check intermittent incident. Refer to GI-39, "Intermittent Incident".

11.CHECK EVAP CANISTER

Weigh the EVAP canister with the EVAP canister vent control valve and EVAP control system pressure sensor attached.

The weight should be less than 2.1 kg (4.6 lb).

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-39, "Intermittent Incident".

NO >> GO TO 12.

12.DETECT MALFUNCTIONING PART

Check the following.

- EVAP canister for damage

- EVAP hose between EVAP canister and vehicle frame for clogging or poor connection

>> Repair hose or replace EVAP canister. Refer to FL-15, "Removal and Installation".

Component Inspection

1.CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

With CONSULT

With CONSULT

- Turn ignition switch OFF.

- Reconnect all harness connectors disconnected.

- Disconnect EVAP purge hoses connected to EVAP canister purge volume control solenoid valve.

- Turn ignition switch ON.

- Select “PURG VOL CONT/V” in “ACTIVE TEST” mode of “ENGINE” using CONSULT.

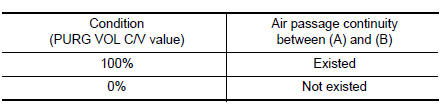

Touch “Qd” and “Qu” on CONSULT screen to adjust “PURG VOL C/V” opening and check air passage continuity of EVAP canister purge volume control solenoid valve as per the following conditions.

Without CONSULT

Without CONSULT

- Turn ignition switch OFF.

- Disconnect EVAP canister purge volume control solenoid valve harness connector.

- Disconnect EVAP purge hoses connected to EVAP canister purge volume control solenoid valve.

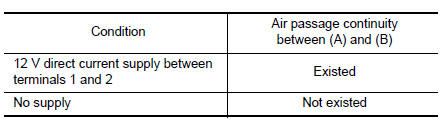

- Check air passage continuity of EVAP canister purge volume control solenoid valve as per the following conditions.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace EVAP canister purge volume control solenoid valve. Refer to EM-27, "Exploded View".

P0441 EVAP Control system

P0441 EVAP Control system

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P0441 is displayed with other DTC such as P2122, P2123, P2127,

P2128 or P2138, first perform

trouble diagnosis for other DTC.

In this evaporative emis ...

P0444, P0445 EVAP Canister purge volume control solenoid valve

P0444, P0445 EVAP Canister purge volume control solenoid valve

DTC Logic

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P0444

PURG VOLUME CONT/V

(Evaporative ...

Other materials:

Component parts

Component Parts Location

ABS actuator and electric unit (control

unit)

IPDM E/R

Brake fluid level switch

Front wheel sensor LH (RH similar)

Rear wheel sensor LH (RH similar)

VDC OFF switch

Steering angle sensor

(view with steering wheel removed)

Sto ...

Engine control system

ENGINE CONTROL SYSTEM : System Description

SYSTEM DIAGRAM

NOTE:

Position switch and clutch pedal position switch are not used in

models with CVT.

ASCD steering switch and brake pedal position switch are used in

models with ASCD.

TCM and transmission range switch are not used in m ...

Component parts

Component parts location

Combination meter

Combination switch (lighting and turn

signal switch)

Key switch (without intelligent key system)

Push-button ignition switch (with intelligent

key system)

Seat belt buckle switch lh

Front door switch lh

Bcm

(view with instrument pane ...