Nissan Sentra Service Manual: System description

Refrigeration system

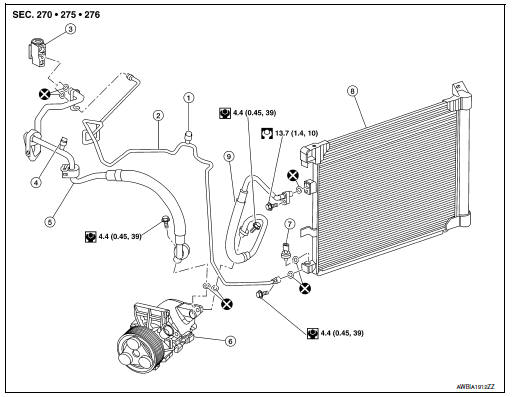

Component part location

- High-pressure service port

- High-pressure pipe

- Expansion valve

- Low-pressure service port

- Low-pressure flexible hose

- Compressor

- Refrigerant pressure sensor

- Condenser and liquid tank assembly

- High-pressure flexible hose

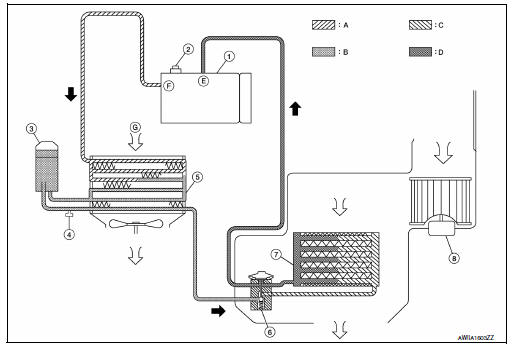

Refrigerant cycle

Refrigerant flow

- Electric compressor

- Pressure relief valve

- Liquid tank

- Refrigerant pressure sensor

- Condenser

- Expansion valve

- Evaporator

- Blower motor

- High-pressure gas

- High-pressure liquid

- Low-pressure liquid

- Low-pressure gas

- Suction port

- Discharge port

- Outside air

Refrigerant Flow

The refrigerant from the compressor flows through the condenser and liquid tank, the evaporator and returns to the compressor. The refrigerant evaporation in the evaporator is controlled by an expansion valve.

Freeze Protection

To prevent the evaporator from freezing up, the evaporator air temperature is monitored by the intake sensor and the voltage signal to the A/C auto amp. makes the A/C relay go OFF and stop the compressor

Refrigerant system protection

Refrigerant pressure sensor

The refrigerant system is protected against excessively high or low pressures by the refrigerant pressure sensor, located on the liquid tank. If the system pressure rises above or falls below the specifications, the refrigerant pressure sensor detects the pressure inside the refrigerant line and sends the voltage signal to the ECM.

The ECM then ceases to supply power to the A/C relay which disengages and stops the compressor when pressure on the high pressure side (as detected by refrigerant pressure sensor) is over approximately 2,746 kPa (28 kg/cm2, 398 psi), or below approximately 120 kPa (1.22 kg/cm2, 17.4 psi).

Pressure Relief Valve

The refrigerant system is also protected by a pressure relief valve, located in the rear head of the compressor.

When the pressure of refrigerant in the system increases to an abnormal level [more than 3,727 kPa (38 kg/ cm2, 540 psi)], the release port on the pressure relief valve automatically opens and releases refrigerant into the atmosphere.

Preparation

Preparation

Special service tool

The actual shape of the tools may differ from those illustrated here.

HFC-134a (r-134a) service tool and equipmen.T.

Do not mix HFC-134a (R-134a) refrigerant and/or its s ...

Basic inspection

Basic inspection

Diagnosis and repair workflow

Workflow

OVERALL SEQUENCE

DETAILED FLOW

1.INTERVIEW CUSTOMER

Interview the customer to obtain as much information as possible about the

conditions and environm ...

Other materials:

Charging system

System Diagram

System Description

The generator provides DC voltage to operate the vehicle's electrical system

and to keep the battery charged.

The voltage output is controlled by the IC regulator.

Component Description

...

CVT Shift selector

Exploded View

Shift selector knob

Lock pin

Knob cover

Position indication panel

Detent switch

Shift lock unit

Park position switch

Shift selector assembly

Shift selector harness assembly

Position bulb

Key interlock rod

With push-button ignition switch

system

Wi ...

Mixture ratio self-learning value

clear

Description

This describes how to erase the mixture ratio self-learning value. For the

actual procedure, follow the instructions

in “Diagnosis Procedure”.

Work Procedure

1.START

With CONSULT

Start engine and warm it up to normal operating temperature.

Select “SELF-LEARNI ...