Nissan Sentra Service Manual: P0125 ECT Sensor

DTC Logic

DTC DETECTION LOGIC

NOTE:

- If DTC P0125 is displayed with P0116, first perform the trouble diagnosis for DTC P0116. Refer to EC- 196, "DTC Logic".

- If DTC P0125 is displayed with P0117 or P0118, first perform the trouble diagnosis for DTC P0117 or P0118. Refer to EC-198, "DTC Logic".

| DTC No. | CONSULT screen terms (Trouble diagnosis content) | DTC detecting condition | Possible cause |

| P0125 | ECT SENSOR (Insufficient coolant temperature for closed loop fuel control) |

|

|

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

>> GO TO 2.

2.CHECK ENGINE COOLANT TEMPERATURE SENSOR FUNCTION

With CONSULT

With CONSULT

- Turn ignition switch ON

- Select “DATA MONITOR” mode of “ENGINE” using CONSULT.

- Check that “COOLANT TEMP/S” is above 10°C (50°F).

With GST

With GST

Follow the procedure “With CONSULT” above.

Is it above 5В°C (41В°F)? YES >> INSPECTION END

NO >> GO TO 3.

3.PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

- Start engine and run it for 65 minutes at idle speed.

- Check 1st tip DTC.

If “COOLANT TEMP/S” indication increases to more than 10°C (50°F) within 65 minutes, stop engine because the test result will be OK.

CAUTION:

Be careful not to overheat engine.

With GST

With GST

Follow the procedure “With CONSULT” above.

Is 1st trip DTC detected? YES >> Proceed to EC-203, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK ENGINE COOLANT TEMPERATURE SENSOR

Check the engine coolant temperature sensor. Refer to EC-197, "Component Inspection".

Is the inspection result normal? YES >> GO TO 2.

NO >> Replace engine coolant temperature sensor. Refer to CO-24, "Exploded View".

2.CHECK THERMOSTAT OPERATION

When the engine is cold [lower than 70В°C (158В°F)] condition, grasp lower radiator hose and confirm the engine coolant does not flow.

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-39, "Intermittent Incident".

NO >> Repair or replace thermostat. Refer to CO-21, "Removal and Installation of Thermostat".

Component Inspection

1.CHECK ENGINE COOLANT TEMPERATURE (ECT) SENSOR

- Turn ignition switch OFF.

- Disconnect ECT sensor harness connector.

- Remove ECT sensor.

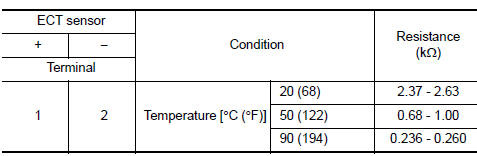

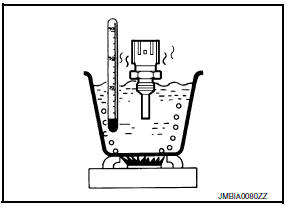

- Check resistance between ECT sensor terminals by heating with hot water as shown in the figure.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace engine coolant temperature sensor. Refer to CO-24, "Exploded View".

P0122, P0123 TP Sensor

P0122, P0123 TP Sensor

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P0122 or P0123 is displayed with DTC P0643, first perform the

trouble diagnosis for DTC P0643.

Refer to EC-353, "DTC Logic".

DTC No ...

P0127 IATSensor

P0127 IATSensor

DTC Logic

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P0127

IAT SENSOR-B1

(Intake air temper ...

Other materials:

Doors

When the doors are locked using one of the

following methods, the doors cannot be opened

using the inside or outside door handles. The

doors must be unlocked to open the doors.

WARNING

Always have the doors locked while

driving. Along with the use of seat belts,

this provides ...

P285A Clutch B Pressure

DTC Logic

DTC DETECTION LOGIC

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

Possible causes

P285A

CLUTCH B PRESSURE

(Clutch B Pressure Disengagement

Performance)

The detection conditions continuously for 200

msec or more und ...

Fuel level sensor signal circuit

Description

The fuel level sensor unit and fuel pump detects the approximate fuel level

in the fuel tank and transmits the

fuel level signal to the combination meter.

Component function check

1.Combination meter input signal

Select meter/m&a on consult.

Using FUEL METER of DATA MONI ...