Nissan Sentra Service Manual: Headlamp

Aiming adjustment

Preparation before adjusting

Before performing aiming adjustment, check the following:

- Ensure all tires are inflated to correct pressure.

- Place vehicle and screen on level surface.

- Ensure there is no load in vehicle other than the driver (or equivalent weight placed in driver's position).

- Coolant and engine oil filled to correct level, and fuel tank full.

- Remove cargo and/or luggage to maintain an unloaded vehicle condition.

- Confirm spare tire, jack and tools are properly stowed.

- Carefully wipe off any dirt from headlamp lens.

Caution:

Do not use organic solvent (thinner, gasoline etc.)

- Place a driver or equivalent weight of 68.5 Kg (150 lb) on the driver seat.

- By hand, bounce the front and rear of the vehicle to settle the suspension and eliminate any static load.

- Place the front tires in the straight ahead position.

- Aim each headlamp individually and ensure other headlamp beam pattern is blocked from screen.

Note:

- For headlamp aiming details, refer to regulations in your area.

- By regulation, no means for horizontal aim adjustment is provided from the factory; only vertical aim is adjustable.

- Use adjusting screw to perform aiming adjustment.

- Perform headlamp aiming if:

- The vehicle front body has been repaired.

- The front combination lamp has been removed or replaced.

- Any outfitting has been installed.

- The vehicle’s standard load condition has been substantially increased.

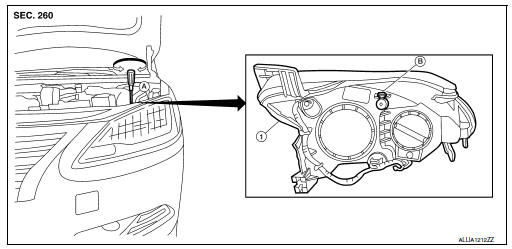

- Front combination lamp

- Suitable tool (for aiming adjustment)

- Adjusting screw

Aiming adjustment procedure

- Position the screen.

Note:

- Stop the vehicle facing the screen

- Place the screen on a plain road vertically.

- Face the screen with the vehicle. Maintain 10 m (33 ft) between the headlamp bulb center and the screen.

- Start the engine. Turn the headlamp (lo) on.

Caution:

Do not cover the lens surface with tape, etc. The lens is made of resin.

Note:

- Aim each headlamp individually and ensure other headlamp beam pattern is blocked from screen.

- For horizontal aiming, adjust headlamp until beam pattern is at horizontal center point.

- Right

- Left

- Center of headlamp bulb (H-V point)

- Cutoff line

- Screen

- Aim evaluation segment

- Step

- Horizontal center line of head lamp

- 30 mm (1.18 in)

- 4 mm (0.16 in)

- 10 m (33 ft)

- 480 mm (18.90 in)

- 160 mm (6.30 in)

- Vertical center line of headlamp

- Basic illuminating area for adjustment should be within the range shown on the aiming chart. Adjust headlamps accordingly.

Front fog lamp

Front fog lamp

Aiming adjustment

PREPARATION BEFORE ADJUSTING

The fog lamp is a semi-sealed beam type which uses a replaceable halogen

bulb. Before performing aiming

adjustment procedure, check the following:

...

Other materials:

Exhaust manifold

Exploded View

CALIFORNIA

Air fuel ratio sensor

Exhaust manifold heat shield (upper)

Exhaust manifold and three way catalyst

Exhaust manifold heat shield (rear)

Exhaust manifold heat shield (front)

Exhaust manifold gasket

Cylinder head

EXCEPT CALIFORNIA

Air fuel ratio ...

Squeak and rattle trouble diagnoses

Work Flow

Customer interview

Interview the customer if possible, to determine the conditions that exist

when the noise occurs. Use the diagnostic

worksheet during the interview to document the facts and conditions when the

noise occurs and any

customer's comments; refer to rf-37, "d ...

Audio system voice commands

To access the audio system voice commands:

Press the button.

Say “Audio”

Speak a command from the following available

commands:

Play (AM, FM, etc.)

Allows user to select radio band

Tune AM (number)

Allows user to tune directly to a desired AM

frequency

Tune FM (number)

...