Nissan Sentra Service Manual: Encoder

Driver side

DRIVER SIDE : Description

Detects condition of the front power window motor lh operation and transmits to main power window and door lock/unlock switch as pulse signal.

DRIVER SIDE : Component Function Check

1. Check encoder operation

Check front door glass lh perform auto open/close operation normally with main power window and door lock/unlock switch.

Is the inspection result normal? Yes >> encoder operation is ok.

No >> refer to pwc-50, "driver side : diagnosis procedure".

DRIVER SIDE : Diagnosis Procedure

Regarding wiring diagram information, refer to pwc-18, "wiring diagram".

Encoder circuit check

1. Check encoder operation

- Connect front power window motor lh.

- Turn ignition switch ON.

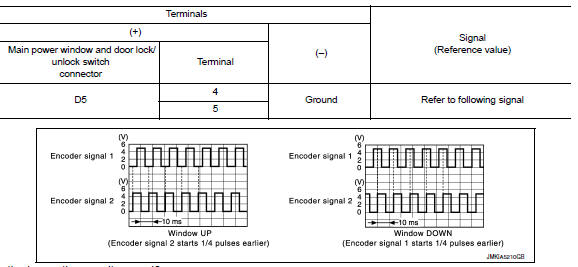

- Check signal between main power window and door lock/unlock switch connector d5 and ground with oscilloscope.

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-39, "Intermittent Incident".

NO >> GO TO 2.

2. Check front power window motor lh power supply

- Turn ignition switch on.

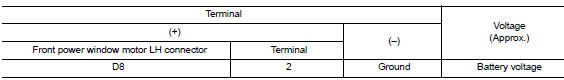

- Check voltage between front power window motor lh connector d8 and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 3.

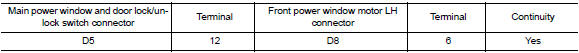

3. Check harness continuity 1

- Turn ignition switch OFF.

- Disconnect main power window and door lock/unlock switch and front power window motor lh.

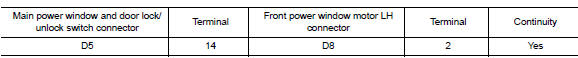

- Check continuity between main power window and door lock/unlock switch connector D5 and front power window motor connector D8.

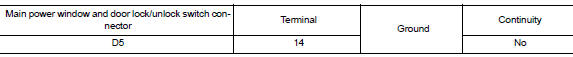

- Check continuity between main power window and door lock/unlock switch connector d5 and ground.

Is the inspection result normal? YES >> Replace main power window and door lock/unlock switch. Refer to PWC-70, "Removal and Installation".

After that, refer to PWC-29, "Work Procedure".

NO >> Repair or replace harness or connectors.

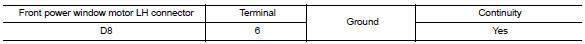

4. Check ground circuit

- Turn ignition switch off.

- Disconnect front power window motor LH.

- Check continuity between front power window motor lh connector d8 and ground.

Is the inspection result normal? Yes >> go to 6.

No >> go to 5.

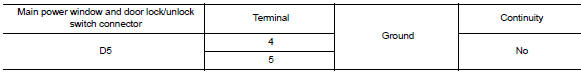

5. Check harness continuity 2

- Disconnect main power window and door lock/unlock switch.

- Check continuity between main power window and door lock/unlock switch connector d5 and front power window motor lh connector d8.

Is the inspection result normal? YES >> Check main power window and door lock/unlock switch. Refer to PWC-36, "POWER WINDOW MAIN SWITCH : Component Inspection".

NO >> Repair or replace the harness or connectors.

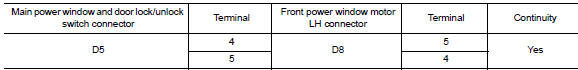

6. Check harness continuity 3

- Disconnect main power window and door lock/unlock switch.

- Check continuity between main power window d5 and door lock/unlock switch connector and front power window motor lh connector d8.

- Check continuity between main power window and door lock/unlock switch connector d5 and ground.

Is the inspection result normal? Yes >> replace front power window motor lh. Refer to gw-16, "removal and installation". After that, refer to pwc-29, "work procedure".

No >> repair or replace harness or connectors.

DRIVER SIDE : Special Repair Requirement

1. Perform initialization procedure

Perform initialization procedure.

Refer to pwc-29, "work procedure".

Is the inspection result normal? Yes >> inspection end.

No >> check intermittent incident. Refer to gi-39, "intermittent incident".

Power window motor

Power window motor

DRIVER SIDE

DRIVER SIDE : Description

Door glass moves up/down by receiving the signal from main power window and

door lock/unlock switch

DRIVER SIDE : Component Function Check

1. Check front po ...

Door switch

Door switch

With intelligent key

WITH INTELLIGENT KEY : Component Function Check

1.Check function

Select DOOR LOCK of BCM using CONSULT.

Select DOOR SW-DR, DOOR SW-AS, DOOR SW-RL and DOOR SW-RR in DATA M ...

Other materials:

Precaution

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT

BELT PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injur ...

P0456 EVAP Control system

DTC Logic

DTC DETECTION LOGIC

This diagnosis detects leaks in the EVAP line between fuel tank and EVAP

canister purge volume control solenoid

valve, using the negative pressure caused by decrease of fuel temperature in the

fuel tank after turning

ignition switch OFF.

If ECM judges there a ...

Precaution for Seat Belt Service

CAUTION:

Before removing the seat belt pre-tensioner assembly, turn the

ignition switch OFF, disconnect both

battery terminals and wait at least three minutes. For approximately three

minutes after the battery

terminals have been removed, it is still possible for the air bag and seat

...