Nissan Sentra Service Manual: Component parts

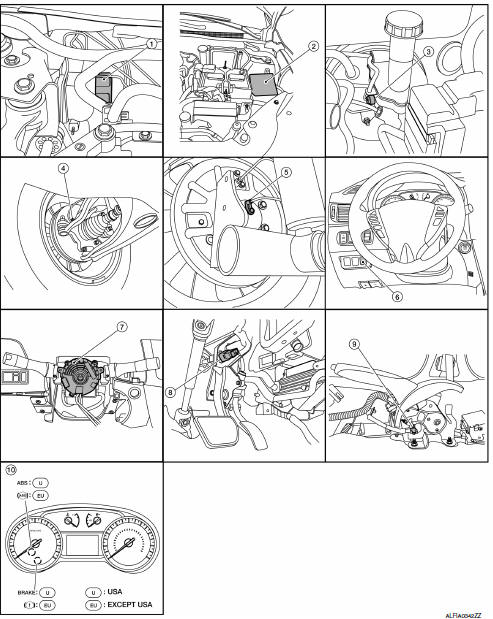

Component Parts Location

-

ABS actuator and electric unit (control unit)

-

IPDM E/R

-

Brake fluid level switch

-

Front wheel sensor LH (RH similar)

-

Rear wheel sensor LH (RH similar)

-

VDC OFF switch

-

Steering angle sensor (view with steering wheel removed)

-

Stop lamp switch

-

Parking brake switch

-

Combination meter

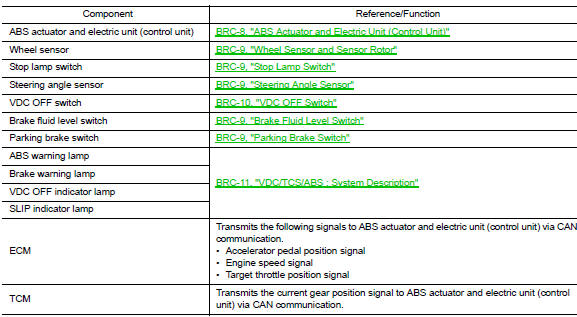

Component Description

ABS Actuator and Electric Unit (Control Unit)

Electric unit (control unit) is integrated with actuator and comprehensively controls VDC function, TCS function, ABS function and EBD function.

ELECTRIC UNIT (CONTROL UNIT)

-

Brake fluid pressure is controlled according to signals from each sensor.

-

If malfunction is detected, the system enters fail-safe mode.

ACTUATOR

The following components are integrated with ABS actuator.

Pump

Returns the brake fluid reserved in reservoir to master cylinder by reducing pressure

Motor

Activates the pump according to signals from ABS actuator and electric unit (control unit).

Motor Relay

Operates the motor ON/OFF according to signals from ABS actuator and electric unit (control unit).

Actuator Relay (Main Relay)

Operates each valve ON/OFF according to signals from ABS actuator and electric unit (control unit).

ABS IN Valve

Switches the fluid pressure line to increase or hold according to signals from control unit.

ABS OUT Valve

Switches the fluid pressure line to increase, hold or decrease according to signals from control unit.

Cut Valve 1, Cut Valve 2

Shuts off the ordinary brake line from master cylinder, when VDC function and TCS function are activated.

Suction Valve 1, Suction Valve 2

Supplies the brake fluid from master cylinder to the pump, when VDC function and TCS function are activated.

Return Check Valve

Returns the brake fluid from brake caliper and wheel cylinder to master cylinder by bypassing orifice of each valve when brake is released.

Reservoir

Temporarily reserves the brake fluid drained from brake caliper, so that pressure efficiently decreases when decreasing pressure of brake caliper and wheel cylinder.

Yaw rate/side/decel G sensor

Calculates the following information that affects the vehicle.

-

Vehicle rotation angular velocity (yaw rate signal)

-

Vehicle lateral acceleration (side G signal) and longitudinal acceleration (decel G signal)

Pressure Sensor

Detects the brake fluid pressure.

Wheel Sensor and Sensor Rotor

NOTE:

-

Wheel sensor of front wheel is installed on steering knuckle.

-

Sensor rotor of front wheel is integrated in wheel hub assembly.

-

Wheel sensor of rear wheel is installed on back plate of rear brake.

-

Sensor rotor of rear wheel is installed on rear brake drum.

-

Never measure resistance and voltage value using a tester because sensor is active sensor.

-

Downsize and weight reduction is aimed. IC for detection portion and magnet for sensor rotor are adopted.

-

Power supply is supplied to detection portion so that magnetic field line is read. Magnetic field that is detected is converted to current signal.

-

When sensor rotor rotates, magnetic field changes. Magnetic field change is converted to current signals (rectangular wave) and is transmitted to ABS actuator and electric unit (control unit). Change of magnetic field is proportional to wheel speed.

Stop Lamp Switch

Detects the operation status of brake pedal and transmits converted electric signal to ABS actuator and electric unit (control unit).

Steering Angle Sensor

Detects the following information and transmits steering angle signal to ABS actuator and electric unit (control unit) via CAN communication.

-

Steering wheel rotation amount

-

Steering wheel rotation angular velocity

-

Steering wheel rotation direction

Brake Fluid Level Switch

Detects the brake fluid level in reservoir tank and transmits converted electric signal from combination meter to ABS actuator and electric unit (control unit) via CAN communication.

Parking Brake Switch

Detects the operation status of parking brake switch and transmits converted electric signal from combination meter to ABS actuator and electric unit (control unit) via CAN communication.

VDC OFF Switch

-

Non-operational status or standby status of VDC and TCS functions can be selected using VDC OFF switch.

VDC OFF indicator lamp indicates the operation status of function. (ON: Non-operational status, OFF: Standby status)

-

VDC OFF indicator lamp turns OFF (standby status) when the engine is started again after it is stopped once while VDC OFF indicator lamp is ON (non-operational status).

System

System

VDC/TCS/ABS

VDC/TCS/ABS : System Diagram

VDC/TCS/ABS : System Description

The system switches fluid pressure of each brake caliper and

each wheel cylinder to increase, to hold, or to

...

Other materials:

Basic inspection

Diagnosis and repair work flow

Work flow

OVERALL SEQUENCE

DETAILED FLOW

1.GET INFORMATION FOR SYMPTOM

Get detailed information from the customer about the symptom (the

condition and the environment when

the incident/malfunction occurs).

Check operation condition of the function th ...

System description

Component parts

Component parts location

Instrument lower finisher

Eco mode switch

The eco mode switch is installed to the instrument lower finisher.

When the ECO mode indicator lamp on the combination meter is

OFF and the ECO mode switch is pressed, the ECO mode is

active and ...

Basic inspection

Inspection and adjustment

Additional service when replacing control unit (bcm)

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT (BCM) : Description

Before replacement

When replacing bcm, save or print current vehicle specification with consult

configuration before replacement.

Note:

If “B ...