Nissan Sentra Service Manual: Battery

How to handle battery

CAUTION:

- If it becomes necessary to start the engine with a booster battery and jumper cables, use a 12-volt booster battery.

- After connecting battery cables, ensure that they are tightly clamped to battery terminals for good contact.

- Never add distilled water through the hole used to check specific gravity.

Methods of preventing over-discharge

The following precautions must be taken to prevent over-discharging a battery.

- The battery surface (particularly its top) should always be kept clean and dry.

- The terminal connections should be clean and tight.

- At every routine maintenance, check the electrolyte level.

This also applies to batteries designated as “low maintenance” and “maintenance-free”.

- When the vehicle is not going to be used over a long period of time, disconnect the battery cable from the negative terminal. (If the vehicle has an extended storage switch, turn it off.)

Work flow

Battery diagnosis with exp-800 ni or gr8-1200 ni

To diagnose and confirm the condition of the battery, use the following special service tools:

- EXP-800 NI Battery and electrical diagnostic analyzer

- Gr8-1200 ni multitasking battery and electrical diagnostic station

Note:

Refer to the applicable Instruction Manual for proper battery diagnosis procedures.

Battery diagnosis without exp-800 ni or gr8-1200 ni

Checking electrolyte level

Warning:

Never allow battery fluid to come in contact with skin, eyes, fabrics, or painted surfaces. After touching a battery, never touch or rub your eyes until you have thoroughly washed your hands. If acid contacts eyes, skin or clothing, immediately flush with water for 15 minutes and seek medical attention.

Failure to do this may cause personal injury or damage to clothing or the painted surfaces.

- Remove the cell plug using a suitable tool.

- Add distilled water up to the max level.

Sulfation

- A battery will be completely discharged if it is left unattended for a long time and the specific gravity will become less than 1.100. This may result in sulfation on the cell plates.

- To determine if a battery has been “sulfated”, note its voltage and current when charging it. As shown in the figure, less current and higher voltage are observed in the initial stage of charging sulfated batteries.

- A sulfated battery may sometimes be brought back into service by means of a long, slow charge, 12 hours or more, followed by a battery capacity test.

Specific gravity check

Note:

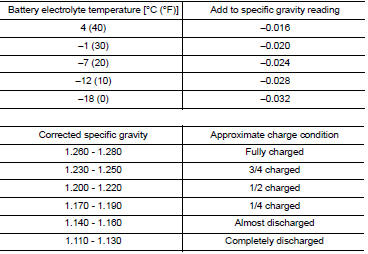

Check the charge condition of the battery.

Periodically check the specific gravity of the electrolyte. Keep a close check on charge condition to prevent over-discharge.

- Read hydrometer and thermometer indications at eye level.

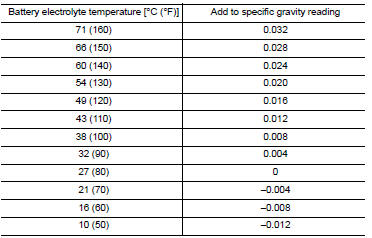

- Use the chart below to correct your hydrometer reading according to electrolyte temperature.

Hydrometer temperature correction

Charging the battery

Caution:

- Never “quick charge” a fully discharged battery.

- Keep the battery away from open flame while it is being charged.

- When connecting the charger, connect the leads first, then turn on the charger. Never turn on the charger first, as this may cause a spark.

- If battery electrolyte temperature rises above 55 В°c (131 В°f), stop charging. Always charge battery at a temperature below 55 В°c (131 В°f).

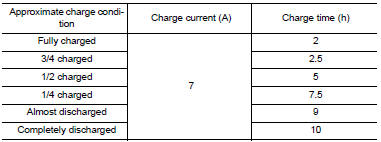

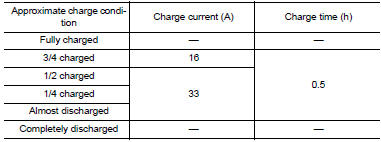

Charging rates (standard charge)

Charging rates (quick charge)

Note:

The ammeter reading on your battery charger will automatically decrease as the battery charges. This indicates that the voltage of the battery is increasing normally as the state of charge improves. The charging amps indicated above refer to initial charge rate.

- If, after charging, the specific gravity of any two cells varies more than 0.050, The battery should be replaced.

Basic inspection

Basic inspection

...

Inspection and adjustment

Inspection and adjustment

Additional service when removing battery negative

terminal

Additional service when removing battery negative

terminal : special repair requirement

Required procedure after battery disconnection

...

Other materials:

Preparation

Special Service Tool

The actual shape of the tools may differ from those illustrated here.

Commercial Service Tools

Clip list

Descriptions for Clips

Replace any clips which are damaged during removal or installation.

...

Basic inspection

Diagnosis and repair work flow

Work flow

Overall sequence

Detailed flow

1.Get information for symptom

Get the detailed information from the customer about the symptom (the

condition and the environment when

the incident/malfunction occurred) using the “diagnostic work sheet”. ( ...

Front fog lamp circuit

Description

The ipdm e/r (intelligent power distribution module engine room) controls the

front fog lamp relay based on

inputs from the bcm over the can communication lines. When the front fog lamp

relay is energized, power

flows from the front fog lamp relay in the ipdm e/r to the front fog ...